Zero-flux Current Clamps: Accuracy without effort from mA to kA

Since 1978, HIOKI has been perfecting fluxgate-based zero-flux technology for the highest measurement accuracy – consistently setting new standards in the precision of current clamps.

Simply clamp and measure.

Whatever you need to measure, HIOKI has the right current clamp for you. From vehicle power testing and production quality control to power electronics and precision waveform analysis, our clamps deliver stable, reliable, and high-accuracy measurements - all without interrupting your setup.

HIOKI’s AC/DC current clamps offer the perfect balance of ease of use and high-precision measurement, thanks to fluxgate-technology in a practical split-core design. Engineered for non-contact current measurement, these clamps enable fast, hassle-free deployment in both laboratory and field applications.

| Large Clamps up to 1 kA/200 kHz | Precision Clamps up to 500 A/2 MHz | Compact Clamps up to 500 A/50 kHz | Ultra-compact Sensors up to 20 A/100 kHz | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | 🔗 CT6846A | 🔗 CT6845A | 🔗 CT6844A | 🔗 CT6843A | 🔗 CT6841A | 🔗 CT6834 | 🔗 CT6833 | 🔗 CT6831 | 🔗 CT6830 |

| Rated Current | ±1000 A | ±500 A | ±500 A | ±200 A | ±20 A | ±500 A | ±200 A | ±20 A | ±2 A |

| Bandwidth | DC – 100 kHz | DC – 200 kHz | DC – 500 kHz | DC – 700 kHz | DC – 2 MHz | DC – 50 kHz | DC – 100 kHz | ||

| Basic Accuracy | ±0.2% rdg | ±0.07% rdg | ±0.3% rdg | ||||||

| Output Voltage | 2 mV/A | 4 mV/A | 10 mV/A | 100 mV/A | 4 mV/A | 10 mV/A | 100 mV/A | 1 V/A | |

| Max. Conductor Diameter | Ø 50 mm | Ø 20 mm | Ø 5 mm | ||||||

Current, Bandwidth & Size: Pick your Clamp

High-accuracy and super-slim “dolphin" current clamps: CT6833 & CT6834

Form follows function: The CT6833 and CT6834 AC/DC Current Clamps deliver near pass-through sensor basic accuracy of ±0.07% packed in an ultra-slim design.

Achieve exceptional measurement precision for demanding tests like WLTP, thanks to fluxgate-technology and a wide operating temperature range.

Key features

- AC/DC Currents up to 500 A (CT6834) | 200 A (CT6833)

- Frequency bandwidth: DC to 50 kHz

- Max conductor diameter: 20 mm

- Operating temperature range: -40°C to +85°C

- DC accuracy of ±0.07% rdg.

See the super-slim CT6833 and CT6834 Current Clamps in action!

These two clamps make a difference with their compact, user-friendly design that enables quick and easy installation. Make current measurements faster and more accurate than ever and with outstanding measurement stability - perfect for real-world testing.

Advanced current sensing up to 1000 A and 2 MHz: the CT684xA-series

The CT684xA series consists of 5 models delivering high-precision AC/DC current measurement with two clamp sizes: for conductors up to 50 mm diameter and up to 1000 A (CT6846A) and for conductors up to 20 mm diameter up to 500 A (CT6844A). Based on fluxgate technology, all clamps provide stable and accurate measurements over bandwidths from DC to 2 MHz.

Ideal for automotive testing, power electronics, and industrial monitoring, these clamps provide reliable insights for high-frequency analysis, inverter efficiency testing, and quality control.

Key features

- AC/DC Currents of 1000 A (CT6846A) | 500 A (CT6845A, CT6844A) | 200 A (CT6843A) | 20 A (CT6841A)

- Frequency bandwidth: DC to 2 MHz*

- Max. conductor diameter: 20 - 50 mm*

- Operating temperature range: -40°C to +85°C

- DC accuracy of ±0.2% rdg.

*see each model for specifications

Ultra-compact current probes up to 20 A: CT6830 & CT6831

HIOKI’s smallest AC/DC current probes CT6830 and CT6831 are engineered to perform in tight spaces. With a practical slide mechanism, they ensure quick installation and stable measurements on conductors in confined environments. These small split-core probes also feature fluxgate-technology, delivering exceptional accuracy and reliability even in extreme conditions.

Both probes easily connect with power analyzers, DAQ systems and oscilloscopes making them the perfect choice for precise current measurements in electronics, vehicle development and power engineering.

Key features

- Rated current: up to 2 A (CT6830) | up to 20 A (CT6831)

- Frequency bandwidth: DC to 100 kHz

- Max. conductor diameter: 5 mm

- Wide temperature range -40°C to +85°C

- High accuracy ±0.3 % rdg.

💡 What’s the right clamp for you? – Here’s your checklist

Which clamp fits your needs best? To find the right one, check your main parameters

- How much current do I need to measure?

Up to 1000 A for power monitoring or 20 A for detailed circuit analysis?

- What bandwidth do I need to cover?

Do I require high-frequency precision up to 2 MHz?

- Where will I use it, and what size do I need?

Ø50 mm for large conductors or Ø5 mm for smaller ones? How much space is available?

The answers will guide you to the right current sensor equipment for your automotive, power electronics, or industrial setups

Do you need a current sensor with a higher bandwidth?

Find our Hall-based current sensors

Power up your precision with our sensor units: CT9555, CT9556, CT9557

The CT955x Sensor Units allow to use HIOKI precision current clamps with any suitable instrument. Select from three models that enable stable power supply and accurate BNC signal output to connect with your power meter, oscilloscope or DAQ-system.

- CT9555: A single-channel unit offering waveform output, ideal for applications requiring accurate waveform measurements from a single source.

- CT9556: This single-channel unit provides waveform and RMS signal output, perfect for applications that require both simultaneously.

- CT9557:This four-channel solution can be used for each channel independently or aggregate all inputs into a single output. Supporting up to four current clamps or sensors, it is ideal for measuring large currents or parallel conductor configurations.

➡ You would like to integrate our clamps?

For other solutions to integrate the HIOKI current clamps or sensors into your measurement system, contact us to get information about the HIOKI ME15W connector specifications.

DC Current Measurement and Bandwidth

Ever wondered why bandwidth matters in DC current measurement? This blog article explores how bandwidth affects accuracy and the ability to capture rapid changes in current. Understanding these factors is key to choosing the right measurement method or sensor type for your application.

“All you needed was a precise sensor to measure DC current – but after talking to HIOKI you ended up ordering a 10MHz AC/DC current sensor… Does HIOKI employ sales magicians who can sell ice to eskimos? Or does bandwidth simply also matter when measuring DC?!"

Analysis, Monitoring and Recording – HIOKI Current Measurement Solutions

High-precision power analysis: PW4001 Power Analyzer

The PW4001 Power Analyzer delivers highest DC power accuracy measurement for development, production, and field testing in a compact 4-channel design. With ±0.04% basic DC accuracy, it ensures precise efficiency analysis, while its selectable 1 ms to 200 ms update rate enables to reliably capture transient fluctuations.

Perfect for WLTP testing, the PW4001 is an essential tool for evaluating energy consumption in hybrid, full-electric, and ICE vehicles. The PW4001 offers a standard CAN interface that supports data input and output, 16 GB of internal storage, and an operating temperature range of -20 ℃ to + 50 ℃. These features make the PW4001 ideal for WLTP tests. The optional DC power input available with some models further optimizes measurements during on-board testing.

This power analyzer also supports motor and inverter measurement, renewable energy, and industrial power system analysis with its wide bandwidth and a motor analysis option.

Key features

- Basic accuracy ±0.04%

- Frequency bandwidth: DC, 0.1 Hz to 200 kHz

- CAN / CAN FD output and input

- Safety rating: CAT II 1500 V DC

- Operating temperature range: -20 ℃ to 50 ℃

Scalable multi-channel current logging: LR8101 & LR8102 Data Loggers

The LR8101 offers 12 power/current channels, while the LR8102 provides up to 120 power/current channels when linking multiple units with optical synchronization. Both support high-precision AC/DC measurements up to 2000 A using HIOKI’s ME15W-compatible sensors with auto recognition at a max. update interval of 5 ms.

Ideal DAQ-system for industrial power monitoring and HVAC performance testing, the LR8102 is perfect for multi-channel applications, while the LR8101 serves as a compact standalone solution.

Key features

- Scalable multi-channel logging – 12 channels (LR8101) or up to 120 channels for power, current and voltage logging

- High-precision AC/DC current measurement up to 2000 A with HIOKI current sensors

- High-Accuracy current and power logging with M7103

- Automatic sensor recognition

- High-speed data acquisition up to 5 ms

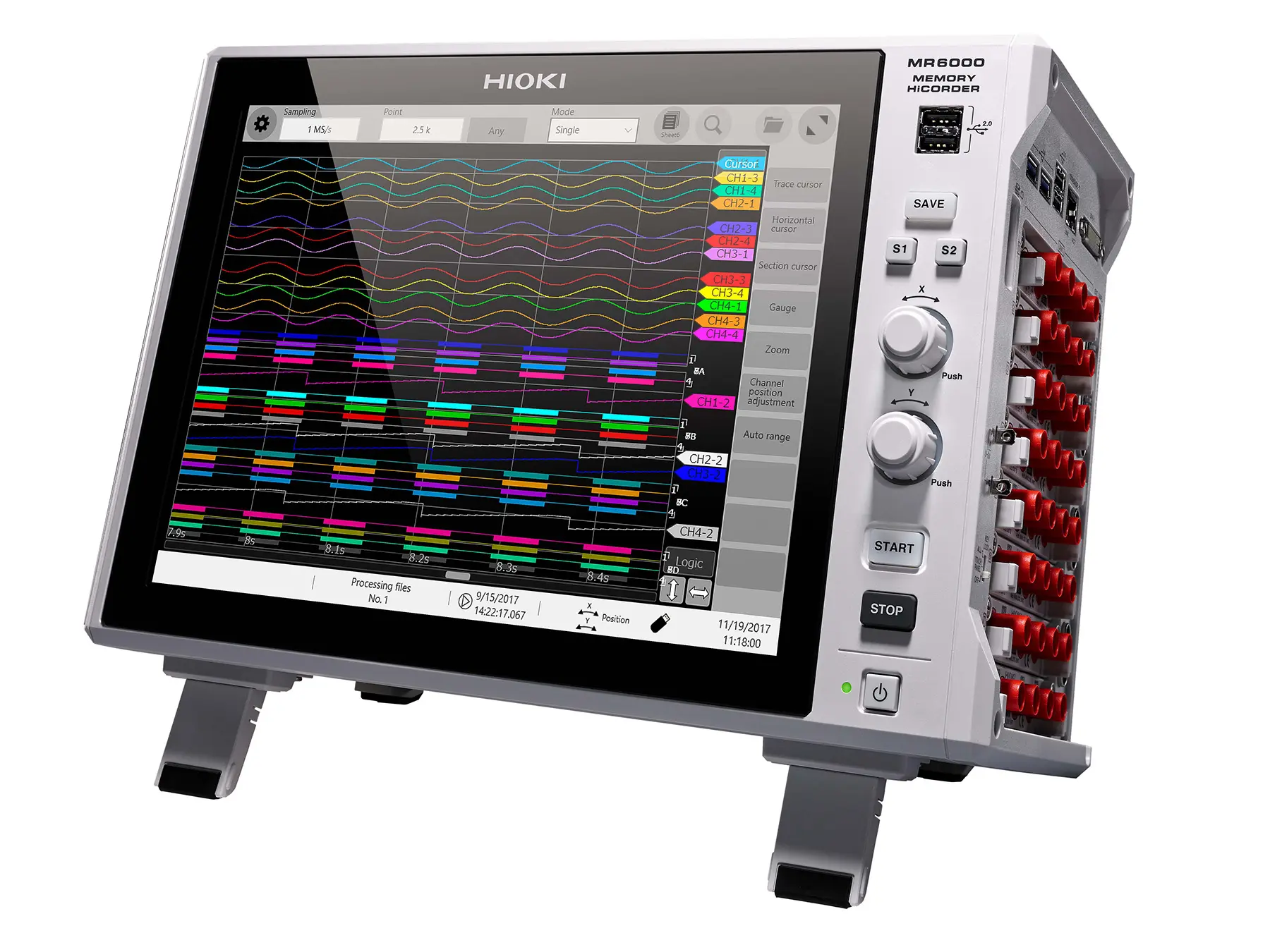

High-speed current measurement + high versatility: MR6000 Memory Recorder

Capture every detail of your current signals with the MR6000 Memory Recorder, delivering high-speed, high-accuracy waveform recording. It pairs with HIOKI’s zero-flux sensors for precise current analysis and features auto sensor recognition, 200 MS/s sampling, and real-time processing. Its modular design is expandable delivering multi-parameter data acquisition.

Ideal for EVs, inverters, power electronics, and industrial diagnostics, this data recorder integrates voltage, frequency, acceleration and strain measurements for comprehensive testing.

Key features

- Up to 200 MS/s sampling for high-speed data acquisition

- 8 slots, up to 32 analog channels for expandable measurement capabilities

- Wide selection of 15 input & 3 output modules

- 12.1-inch capacitive touch screen for intuitive operation and enhanced analysis capabilities

- Direct measurement of up to 1000 VDC/700 VAC

MR6000

HIOKI MR6000 - 32-channel modular memory recorder, 200 MS/s, 1000V, touchscreen

HIOKI MR6000 32-channel modular memory recorder with 200 MS/s sampling, 1000 V isolated inputs and intuitive touchscreen for high-speed multi-channel waveform capture and analysis. Order now from HIOKI Europe.

Zero-Flux Current Sensors Explained: Like in “Back to the Future”?

Ever wondered how zero-flux current sensors work? This blog takes you behind the science of this cutting-edge technology - exploring its principles, applications, and why it might sound familiar. Check it out:

To the Blog

Do you remember the “flux capacitor” that Doc Brown invented in Back to the Future? It was the heart of the DeLorean, enabling time travel when powered with 1.21 GW of energy. While zero-flux current sensors won’t send you through time, they do use a fascinating principle that delivers unmatched accuracy in current measurement.

Are Fluxgate-based current clamps for you?

In a nutshell: Yes - if you aim for power measurements, you measure high currents up to 1000 A, and your bandwidth is not higher than 2 MHz, zero-flux current clamps based on fluxgate-technology are for you.

Watch this 1-minute video to get a quick breakdown of the key differences between fluxgate and Hall-based sensors.

à

Do you need to measure current with more bandwidth?

For high-bandwidth measurement solutions up to 120 MHz with low currents starting from 200 µA, check out the HIOKI the Hall-based sensors.

Precise Current Clamps: Improve Your Applications

HIOKI current clamps enable precise, real-time measurement of high currents without disrupting setups, ensuring accuracy and efficiency in dynamic waveform analysis across key industries.

Power Electronics & Inverter Testing

Optimize inverter output and power conversion for renewable energy and industrial systems, ensuring high efficiency and stability.

Automotive & EV Testing

Evaluate battery current and motor drive efficiency in EVs and hybrids, ensuring WLTP & SAE J1634 compliance for optimized energy management.

Industrial Power Monitoring

Monitor high-current loads and AC/DC distribution in factories and heavy machinery, detecting anomalies and improving efficiency.

Circuit Testing & Low-Current Measurements

Capture precision micro-currents and circuit stability in compact electronics, analyzing power consumption for efficient design.

Battery & Power Supply Analysis

Assess charge/discharge cycles, load response, and transient behavior to ensure stable power delivery and extended battery life.