CT6830 - Ultra-compact AC/DC Current Probe, 2 A / 100 kHz

Ultra-small, zero-flux clamp-on AC/DC Current Probe using flux gate detection, high accuracy ±0.3% rdg., wide temperature range -40 to 85 °C, measurable current up to 2 A, ME15W connector

€1,628.00*

Content:

1 Each

In stock in Germany

€1,628.00*

CT6830 - Ultra-compact AC/DC Current Probe, 2 A / 100 kHz

Available stock:

1

Product number:

CT6830

EAN:

4536036015313

Length:

77 mm

Width:

14 mm

Height:

23 mm

Weight:

0.16 kg

Product information CT6830 - Ultra-compact AC/DC Current Probe, 2 A / 100 kHz

Key Specifications

- High Accuracy ±0.3% rdg.

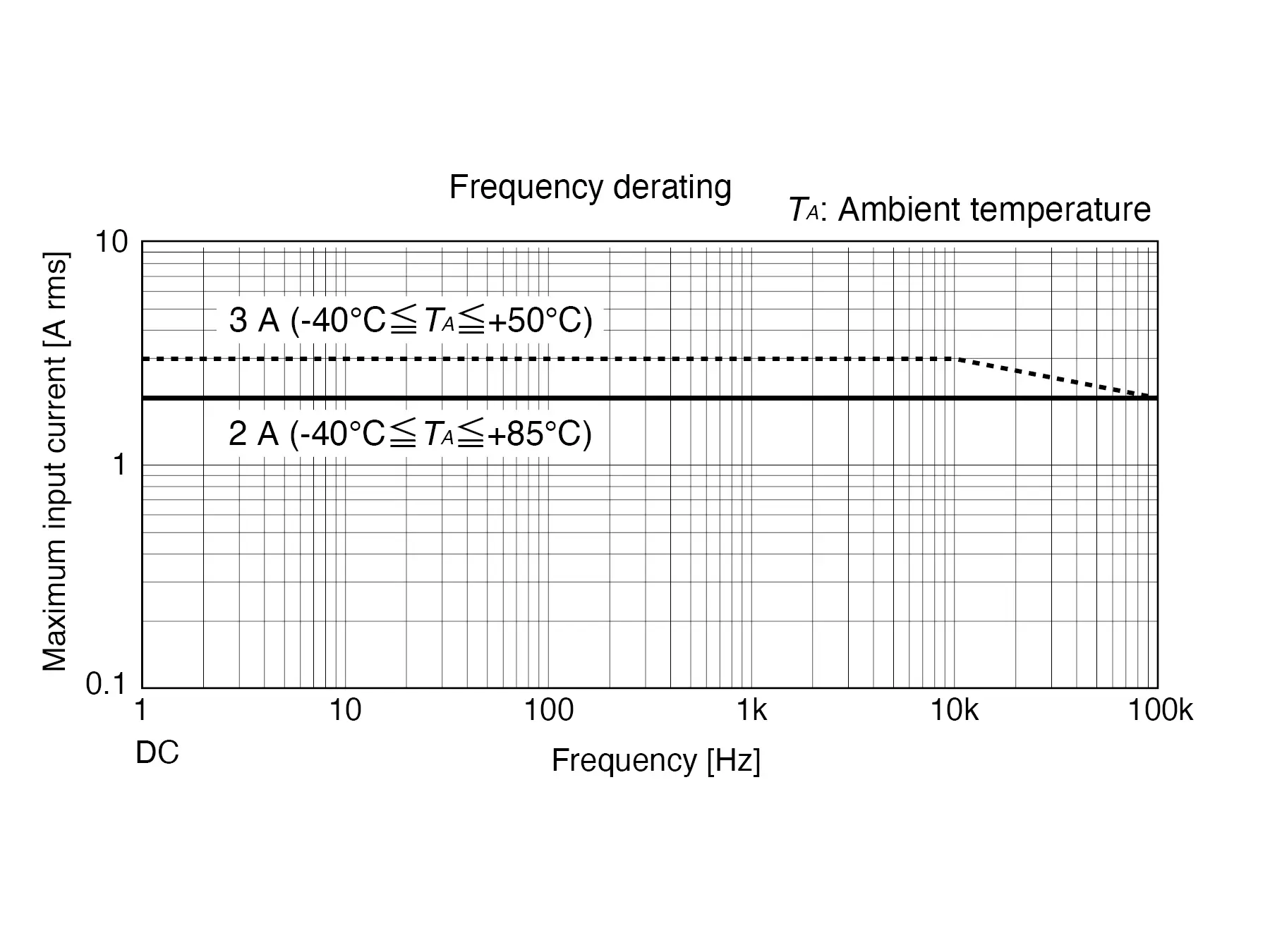

- Measurable current up to 2 A

- Ultra small size sensor with slide open/lock mechanism

- Wide temperature range -40 to 85 oC

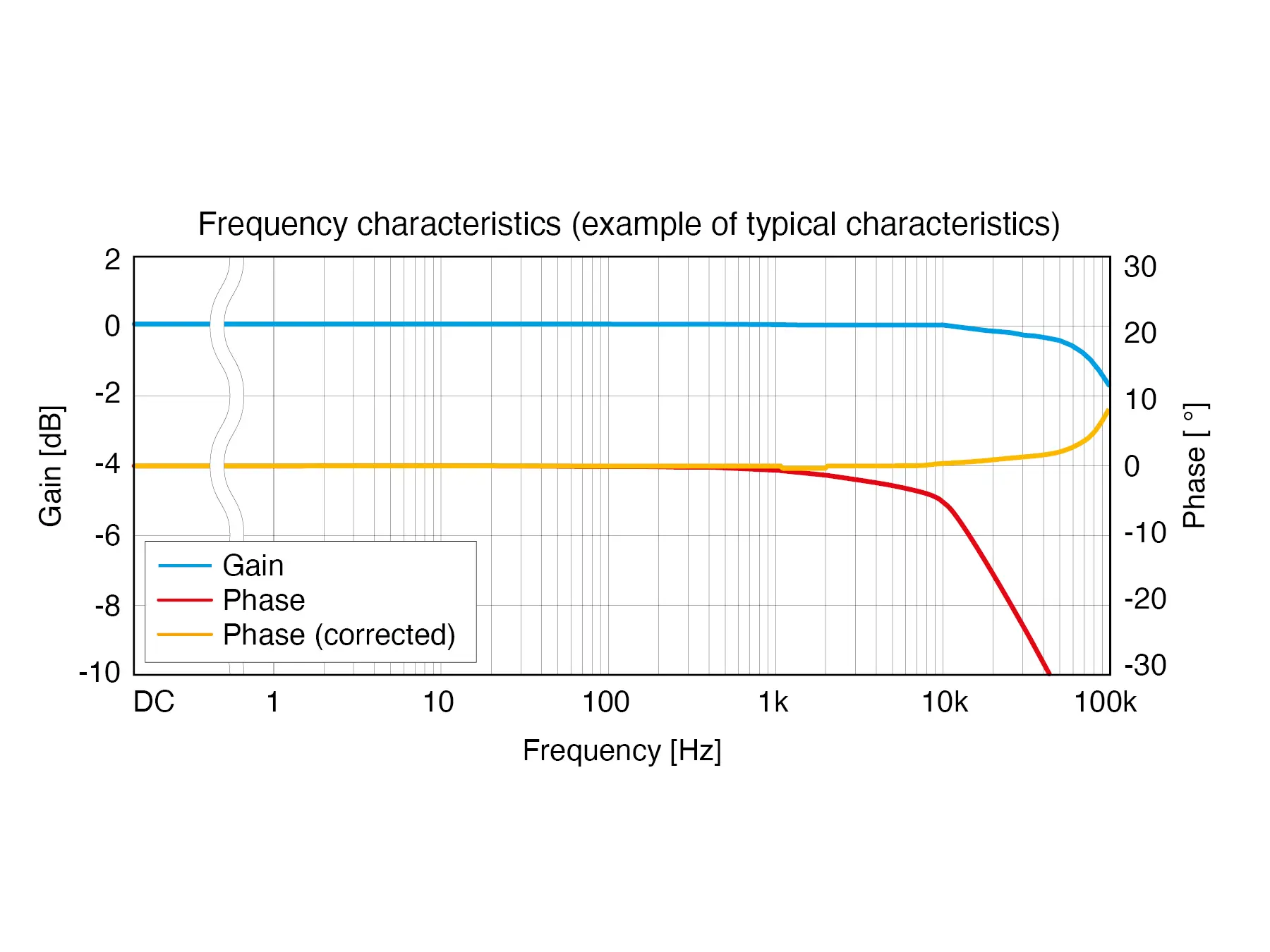

- Bandwidth DC to 100 kHz

Unique Advantages

- Easy installation, even in tight spaces

- Accurate low current measurement

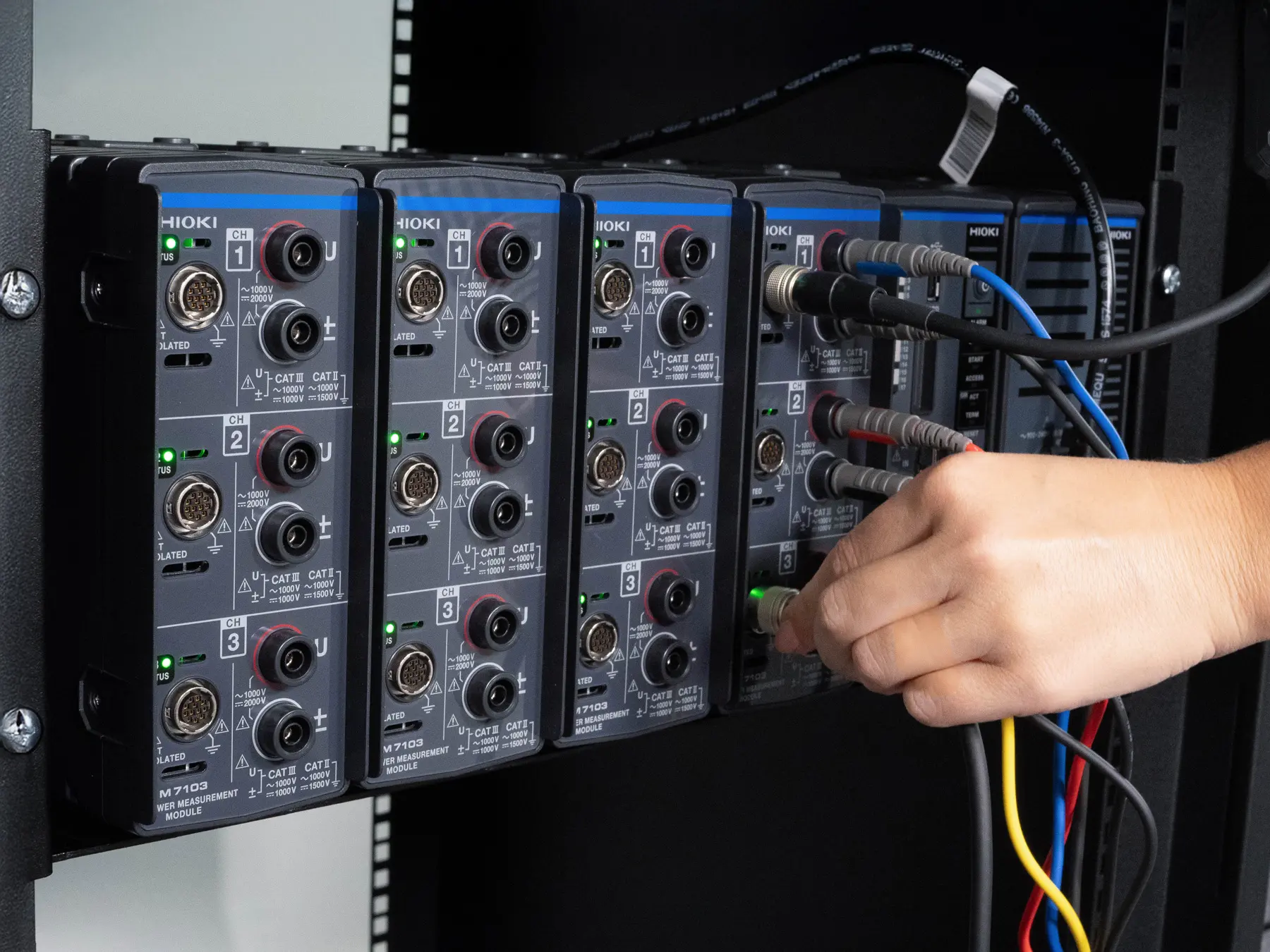

- Automatic recognition by HIOKI Power Analyzer PW8001

- Allows for stable measurement from Alaska to the Sahara

Typical Applications

- Development and analysis tool for improving the fuel efficiency of electrical vehicles

- Consumption measurement of low power EV circuits like ECUs, interior lighting etc.

- Optimizing the overall energy consumption of low power circuits in EVs to extend the driving range

- Optimizing the overall energy consumption of low power circuits in electrical construction vehicles or electrical agricultural vehicles to extend the time between charging

Detailed Product Overview

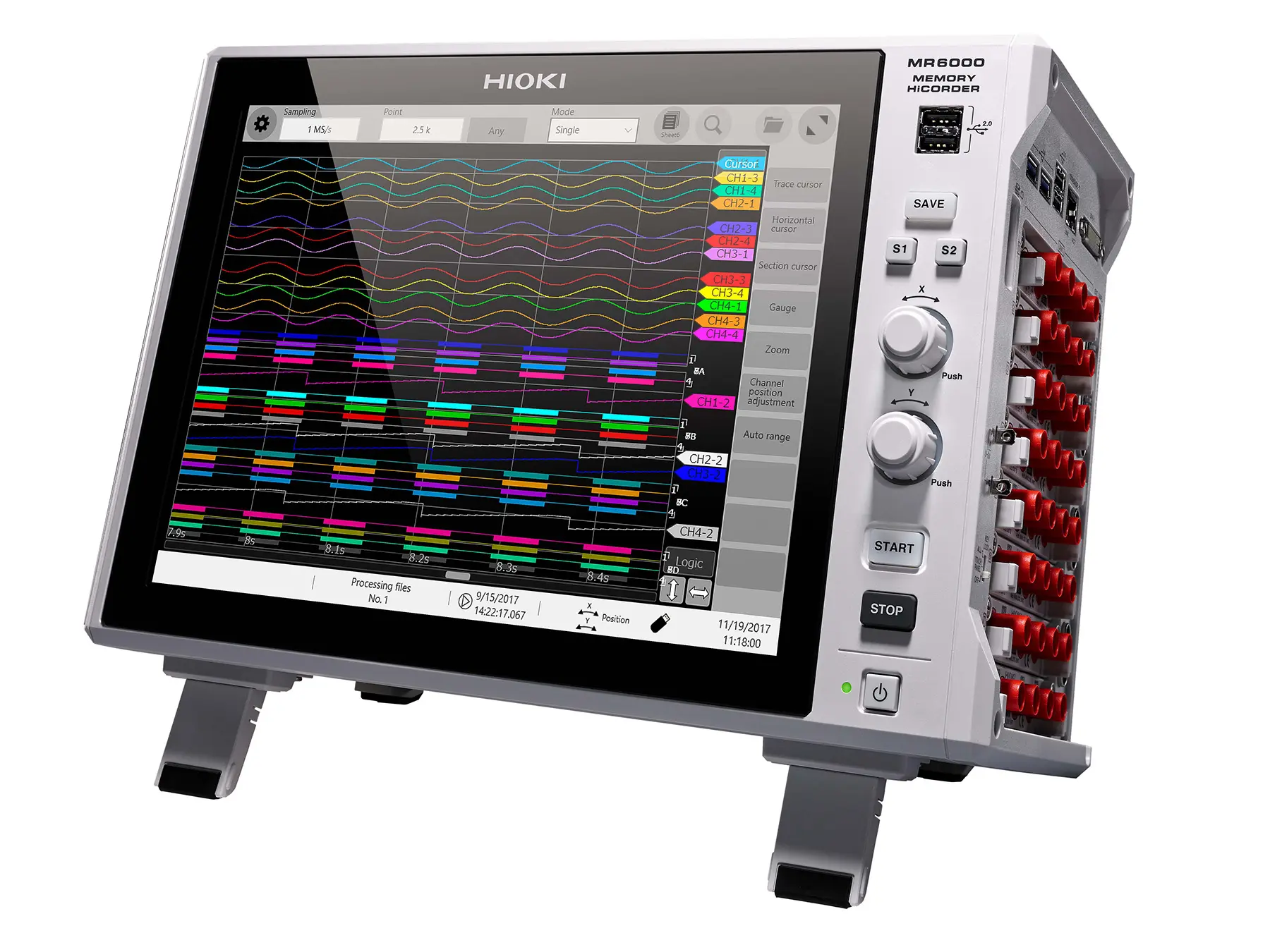

The ultra-small CT6830 Current Probe with its slide-open/lock feature is one of the smallest high-accuracy sensors on the market. Contactless measurement of currents from 100 µAup to 2 A AC/DC and frequencies up to 100 kHz are possible even in the most confined spaces with a basic accuracy of ±0.3 % rdg. This compact sensor gives development engineers of EVs, electrical trucks, buses, construction, and agricultural vehicles the possibility to accurately monitor energy consumption under the most extreme temperature conditions.Designed to be used in combination with a HIOKI Power Analyzer, Memory Recorder or Data Logger, the CT6830 provides detailed energy consumption insight for example of a vehicle under test. Combined with a CT9555, CT9556 or CT9557 Power Supply Unit, the CT6830 Current Probe can also be connected to third party equipment like for instance a DAQ system or an oscilloscope.

Zero-flux Current Clamps: Accuracy without effort from mA to kA

- CT6830

- Colored labels (for channel identification)

- Carrying case

- Instruction Manual

- Operating Precautions

-

Product catalog with data sheet, current sensors & current probes series (English)15,061 KB pdf

-

Product brochure with data sheet, comptact current probes/current sensors CT6830, CT6831, CT6833, CT6834, CT7812, CT7822 (English)2,439 KB pdf

-

Instruction Manual, AC/DC CURRENT PROBE CT6830, CT6831 (English)1,372 KB pdf