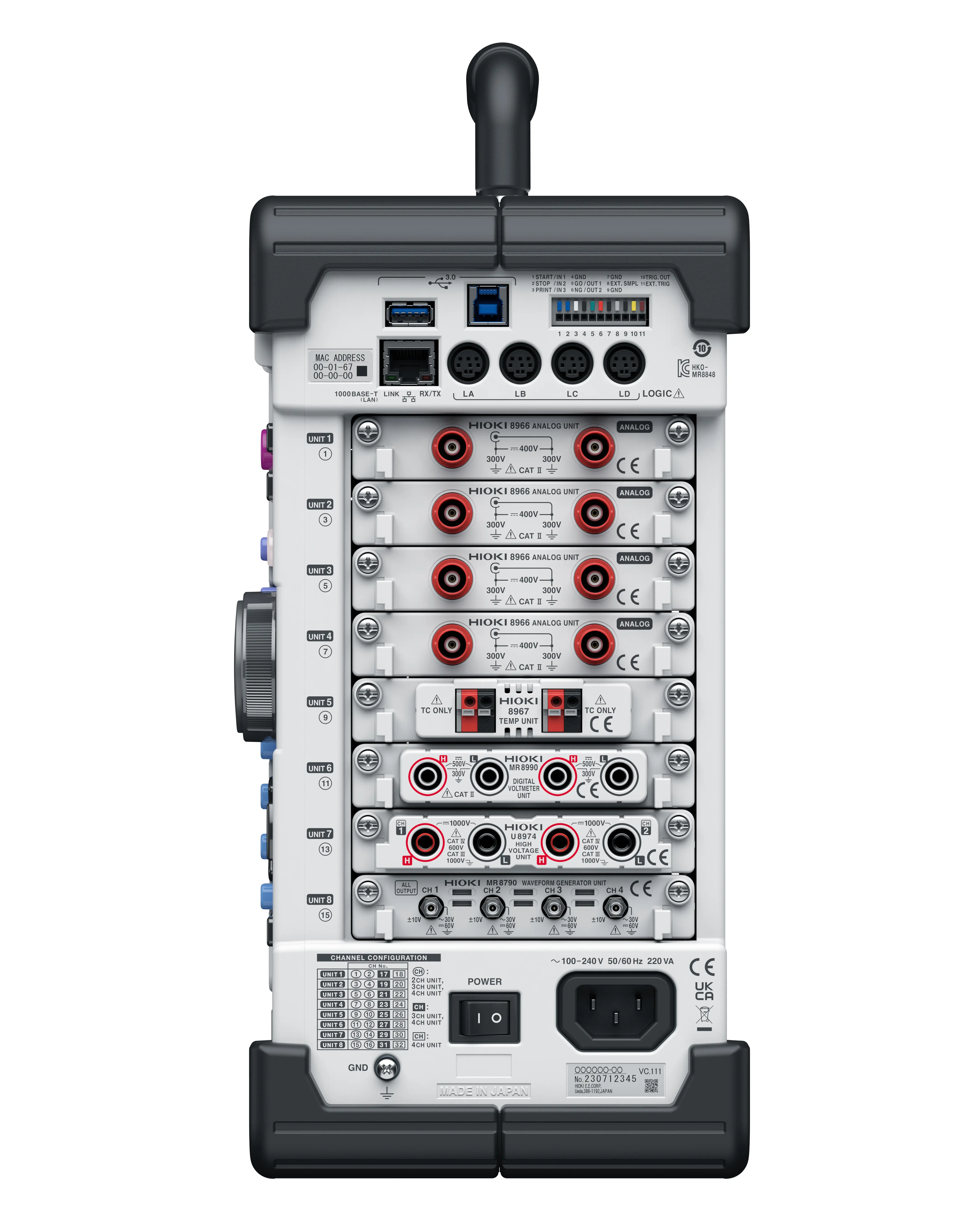

MR8848 - Modular 32-channel memory recorder, 20 MS/s, 1000 V direct input, rugged design

Modular memory recorder, up to 32 analog and 16 logic channels, max. sampling rate 20 MS/s, max 1000 VDC isolated direct voltage input, 1 TB storage with SSD option, optional real-time saving, rugged design, AC or DC power supply

Product information "MR8848 - Modular 32-channel memory recorder, 20 MS/s, 1000 V direct input, rugged design"

Banner Specs

- 8 slots, up to 32 isolated analog and 16 logic channels simultaneously

- High-speed sampling with up to 20 MS/s

- Max. 1000 VDC, 700 VAC

- Real-time saving directly to optional 1 TB SSD

- AC or DC power supply

USPs

- Operation with an external DC power supply (10 to 28 V)

- Immediate, tamper-proof printout of measurement data directly at the test site

Applications

- Evaluation of backup response time during power failures in UPS and data centers

- Monitoring of hydropower turbine control and shutdown after sudden load loss

- Measurement of phase response timing to ensure safe disconnection of circuit breakers

- Monitoring of drive, brake, and vibration data during real railway test runs

- Waveform-based pass/fail judgment of welding quality

- Versatile tool for general maintenance applications which require off-grid highchannel, high-voltage recording

In Detail:

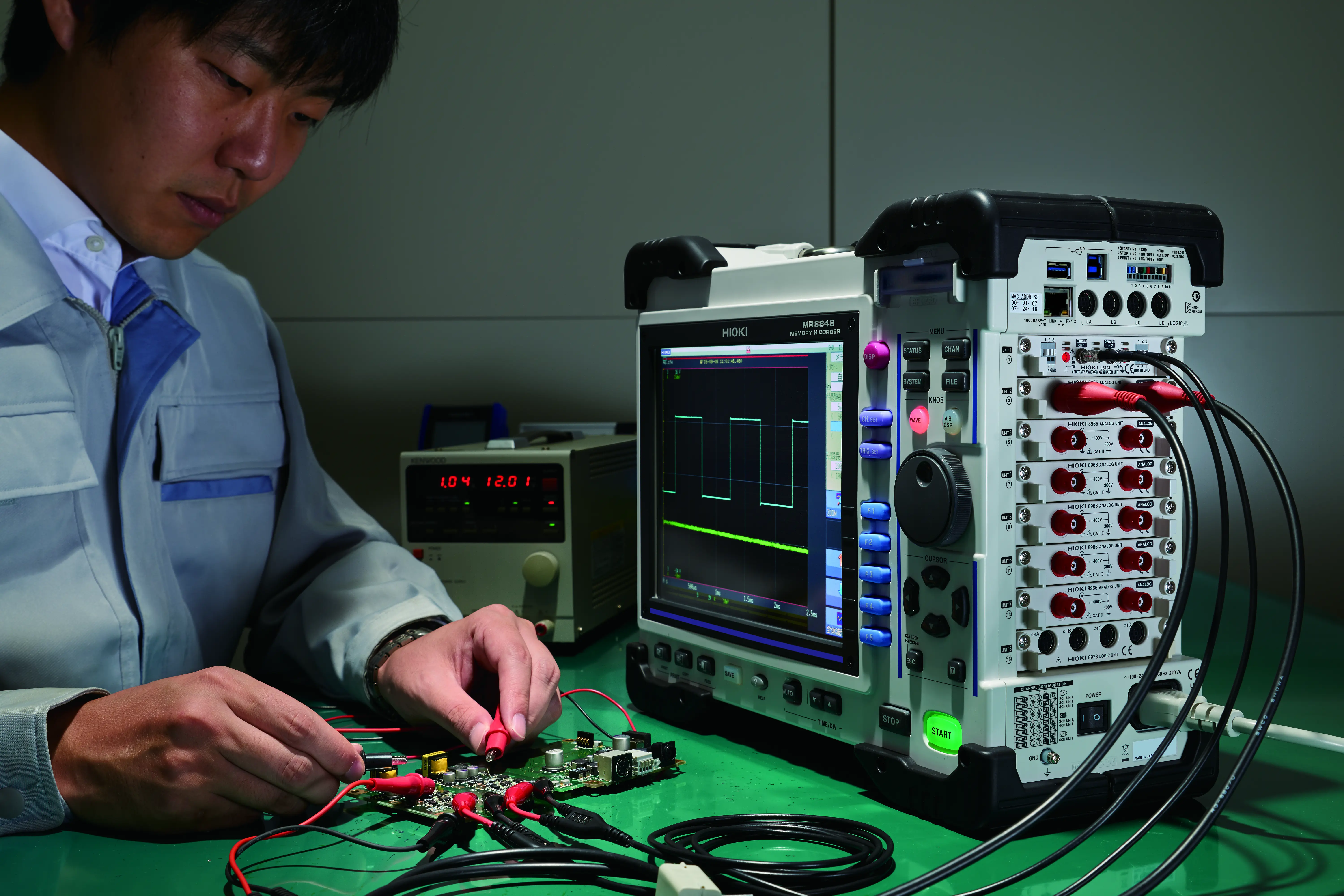

The MR8848 Memory Recorder is a modular, high-speed data acquisition system designed

for accurate waveform recording under demanding conditions. Its rugged construction and

shock-resistant housing make it suitable for both field and lab environments, especially

where vibration, temperature fluctuations, or harsh handling are expected. With a buttonoperated interface and robust design, the MR8848 is intended for long-term, real-world

testing where reliable performance is essential. The system features eight input slots and supports a broad range of interchangeable

modules, offering flexibility for various measurement scenarios. It can simultaneously record

multiple physical parameters – including voltage, current, logic, temperature, vibration,

pressure, and strain – facilitating comprehensive analysis of complex systems. Users can

configure the system for either simultaneous isolated measurement on up to 32 analog

channels, or for high-speed acquisition at up to 20 MS/s, depending on the selected

modules. For high-voltage measurements, another specialized module enables direct input

up to 1000 VDC or 700 VAC. The MR8848 enhances flexibility by enabling direct connection

to HIOKI’s high-accuracy current sensors. Wideband current probes like the CT6711 can be

used together with analog modules such as the U8978. Dedicated current modules, including

the U8977 and 8971, provide accurate measurements across a broad current range and are

designed to work effortlessly with precision clamps and sensors like the CT6841A or

CT6904A. These specialized current modules automatically detect and supply power to

connected HIOKI sensors and clamps, making setup simple and efficient.

Four built-in logic inputs support up to 16 logic channels when used with 4-channel logic

probes. If additional logic channels are needed, logic input modules can be added to further

expand capacity.

Three compatible output modules provide functions such as pulse output and waveform

generation for signal testing and simulation. With the Arbitrary Waveform Generator Module

U8793, users can program and output custom waveforms, making it perfect for replicating

and simulating anomalies. The free SF8000 software makes it easy to create waveforms by

entering data directly and supports tasks like simulating noise or combining waveforms for

complex applications.

To support extended and uninterrupted recordings, the MR8848 features the optional realtime saving function MR9001-01 that enables data to be written directly to the optional 1 TB

SSD or to another external storage, e.g. SD card or USB drive, during measurement. Unlike

conventional systems that rely on internal memory buffers, this approach eliminates the need

to pause testing for data offload, allowing continuous acquisition over long durations. In

addition, real-time saving minimizes the risk of data loss in the event of unexpected power

interruptions, ensuring stable and reliable data logging throughout the measurement process.

The DC Power Unit 9784 is a factory-installed option for the MR8848 Memory Recorder,

enabling operation from external DC sources between 10 V and 28 V – such as vehicle

batteries. This wide input range removes the need for AC power or external converters,

making it ideal for field measurements, mobile testing, and other demanding environments.

Seamlessly integrated during production, the 9784 provides a compact and reliable power

solution for use on the go.

The U8351 Printer Unit is a factory-installed option for the MR8848 Memory Recorder that

enables immediate, tamper-proof printouts of waveform data and measurement results

directly at the test site. It is ideal for applications requiring verifiable hard copies, such as

regulatory documentation, service reports, or customer acceptance records. The printer is

especially useful in environments where digital media are impractical or restricted, providing

fast documentation without needing a PC or USB storage.

Included software tools support a smooth workflow. Use the free MR6000 Viewer and

Waveform Viewer to display, analyze, and export your data with ease. For more advanced

tasks, the 9335 Wave Processor adds powerful processing and batch conversion features.

Integration with LabVIEW, MATLAB, and operation via SCPI commands allows flexible

automation and control.

The MR8848 is widely used across a range of infrastructure and transport sectors, where its

high-speed, multi-channel capability and modular input options make it a powerful tool for

system diagnostics and validation. In electric power systems, it supports UPS operation

testing, ensuring reliable backup activation by recording voltage, current, and temperature

behavior across both input and output sides. In hydropower generation, it enables detailed

load rejection testing, capturing multiple signals such as turbine speed, generated current,

and water pressure to verify that the turbine shuts down safely after a sudden load drop.

For high-voltage circuit breaker testing, the MR8848 precisely measures the time difference

between command signals and contact response across all three phases, helping identify

switching delays and ensuring timing compliance. In the railway sector, it records drive motor

voltage and current, vehicle speed, brake pressure, and vibration during actual operation,

making it a key solution for correlating multi-parameter behavior and validating safety-critical

subsystems.

- MR8848 Memory Recorder

- Startup guide

- Precautions for use

- Power cord

- Recording Paper 9231 and roll paper attachment (when Printer Unit U8351 is installed)

-

Product brochure with data sheet, Modular Memory Recorder MR8848 (English)5,171 KB pdf

-

Data sheet, Modular Memory Recorder MR8848 (English)3,111 KB pdf

-

Instruction Manual, Modular Memory Recorder MR8848 (English)11,435 KB pdf

-

Product brochure with data sheet, Waveform Generator System U8793 (English)3,050 KB pdf