6

Tags

Wireless logging: The DAQ game-changer

As measurement demands become more complex and

dynamic, the choice of modular and wireless data acquisition systems, such as

the LR8450-01 Data Logger, is no longer just a convenience - it's a strategic

enabler. Data acquisition devices now offer the precision of lab-grade

instrumentation combined with the freedom of untethered deployment.

Back to the Future: The story continues...

A little while ago I had the idea to explain the principle of HIOKI's zero-flux current sensors by referring to the movie "Back to the Future". However, my idea turned out to be bit flawed, because I grew up with the German (dubbed) version of the film, and in German the famous "flux capacitor" was called "Fluxkompensator" - or "flux compensator" in English.

Where has all the power gone?

Energy efficiency is essential for creating a low-emission or even carbon-neutral future. It plays a crucial role in the transition from combustion engines to electric vehicles and minimizing the impact of power-hungry AI applications on data center energy consumption. Understanding where power is lost – whether in converters, motors, or data centers – is key to unlocking significant efficiency gains and addressing the growing demand for energy in a sustainable way.

DC Current Measurement and Bandwidth

All you needed was a precise sensor to measure DC current, and after talking to HIOKI you ended up ordering a 10MHz AC/DC current sensor… Does HIOKI employ sales magicians who can sell ice to eskimos? Or does bandwidth also matter when measuring DC?

Your Path to Better Energy Efficiency: Current Mapping

How can you optimize the energy efficiency of EVs and Internal Combustion Engine vehicles? Discover how precise current mapping and compact sensor design are revolutionizing automotive testing. Accurately measuring current consumers in a vehicle is crucial for enhancing performance, reliability, and energy management. Based on this critical data, engineers can identify inefficiencies and optimize the vehicle's electrical systems, leading to better fuel economy and extended driving ranges.

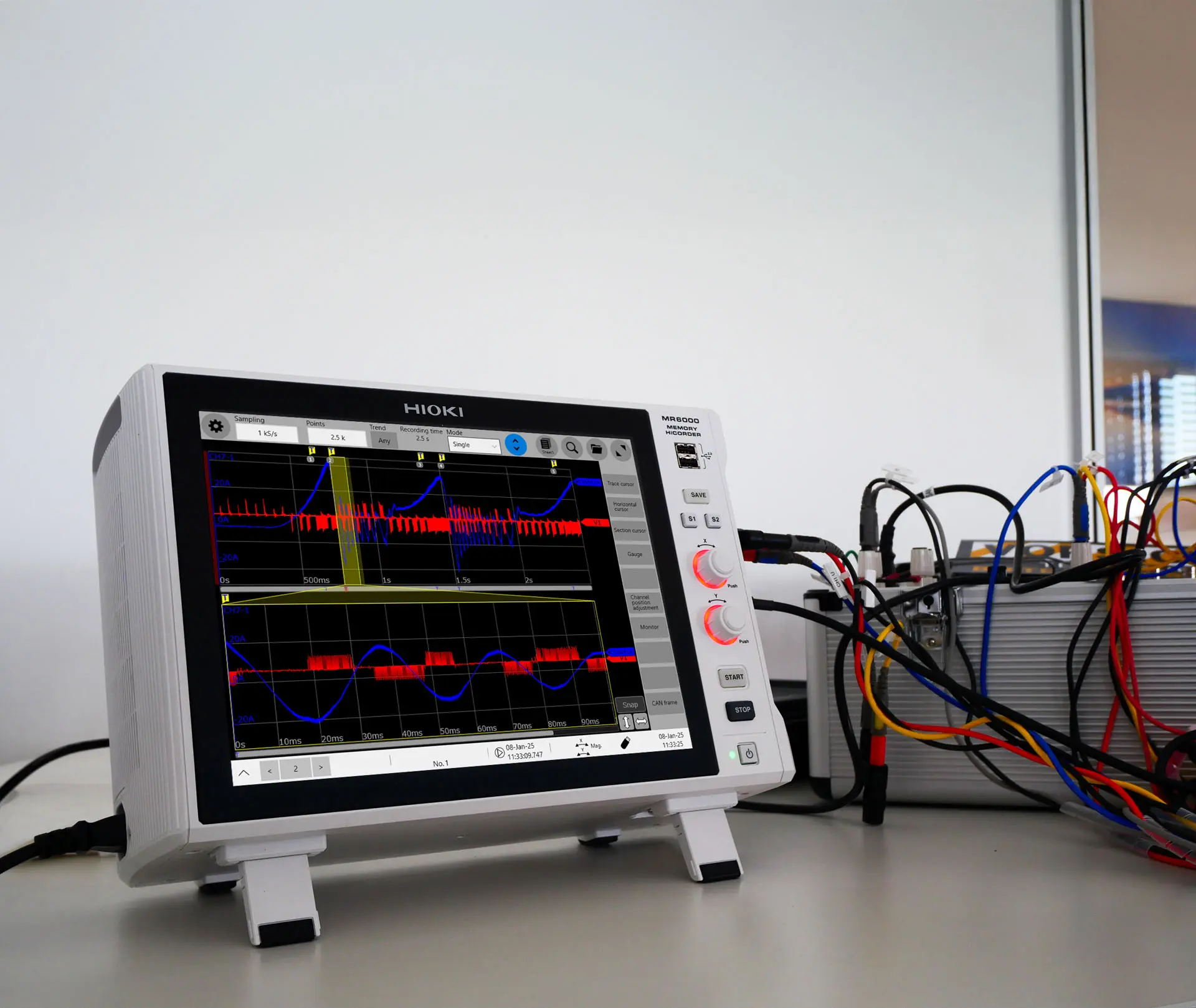

Never Miss a Beat: Choosing the Right Sampling Rate for Data Acquisition

The sampling rate is the heartbeat of data acquisition systems, defining how well a signal is captured and providing a key factor in ensuring data reliability for further analysis. Whether you're monitoring fast transients in electronic components or tracking long-term environmental trends, choosing the right rate balances precision and practicality: Too fast, and you may drown in unnecessary data—too slow, and critical details may be lost.

The Next Generation Power Analyzer: Perfect for SiC & GaN

A new generation power analyzer sets a new industry standard with unrivalled accuracy, providing the best solution for high-frequency and high-power measurements. This allows ultimate efficiency measurements from state-of-the-art SiC and GaN based applications to complex multi-motor drivetrain power analysis.

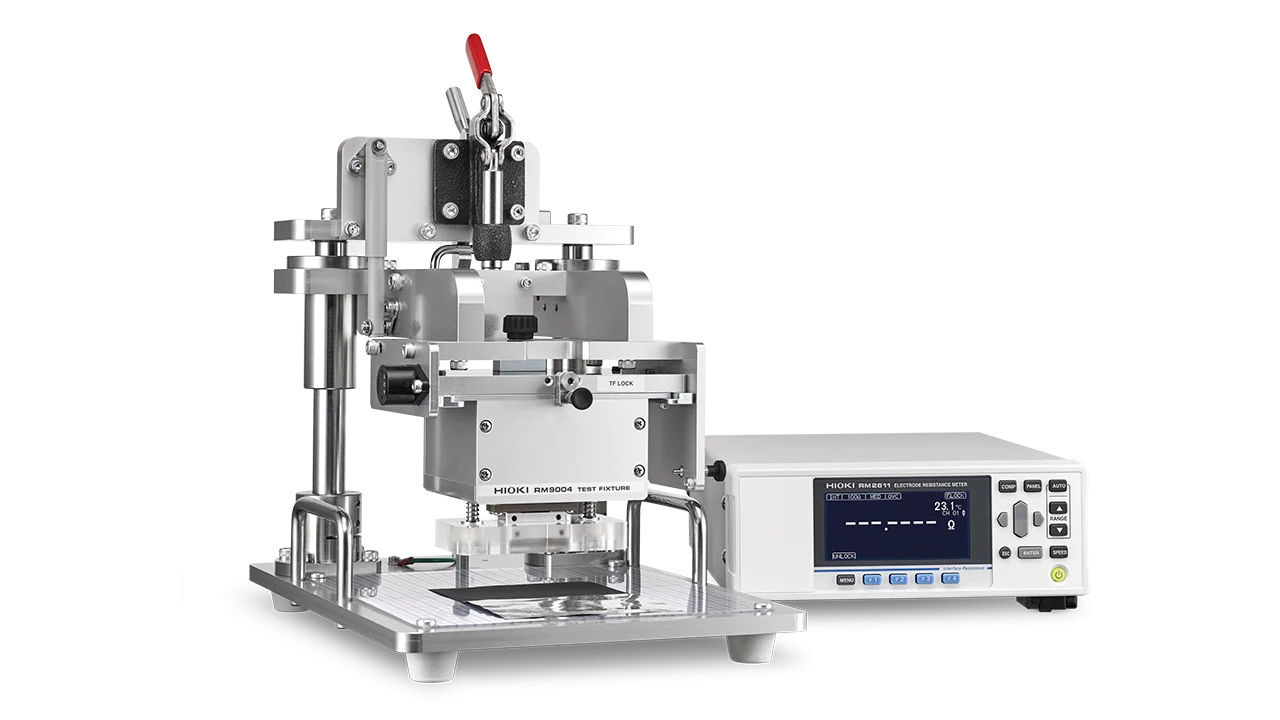

A dedicated resistance meter? Here is when it makes sense…

Measuring DC resistances is one of the functions pretty much every bench multimeter provides. Then why would you need a separate resistance meter?

What’s special about HIOKI’s AC Leakage Current Clamps?

No matter if they are based on hall-sensor or zero-fluxgate technology: HIOKI is famous for their high-end AC/DC current sensors – and they have been for many years. Given that history and experience, it is not surprising that HIOKI also offers a large variety of clamp meters, including three AC leakage current clamps.

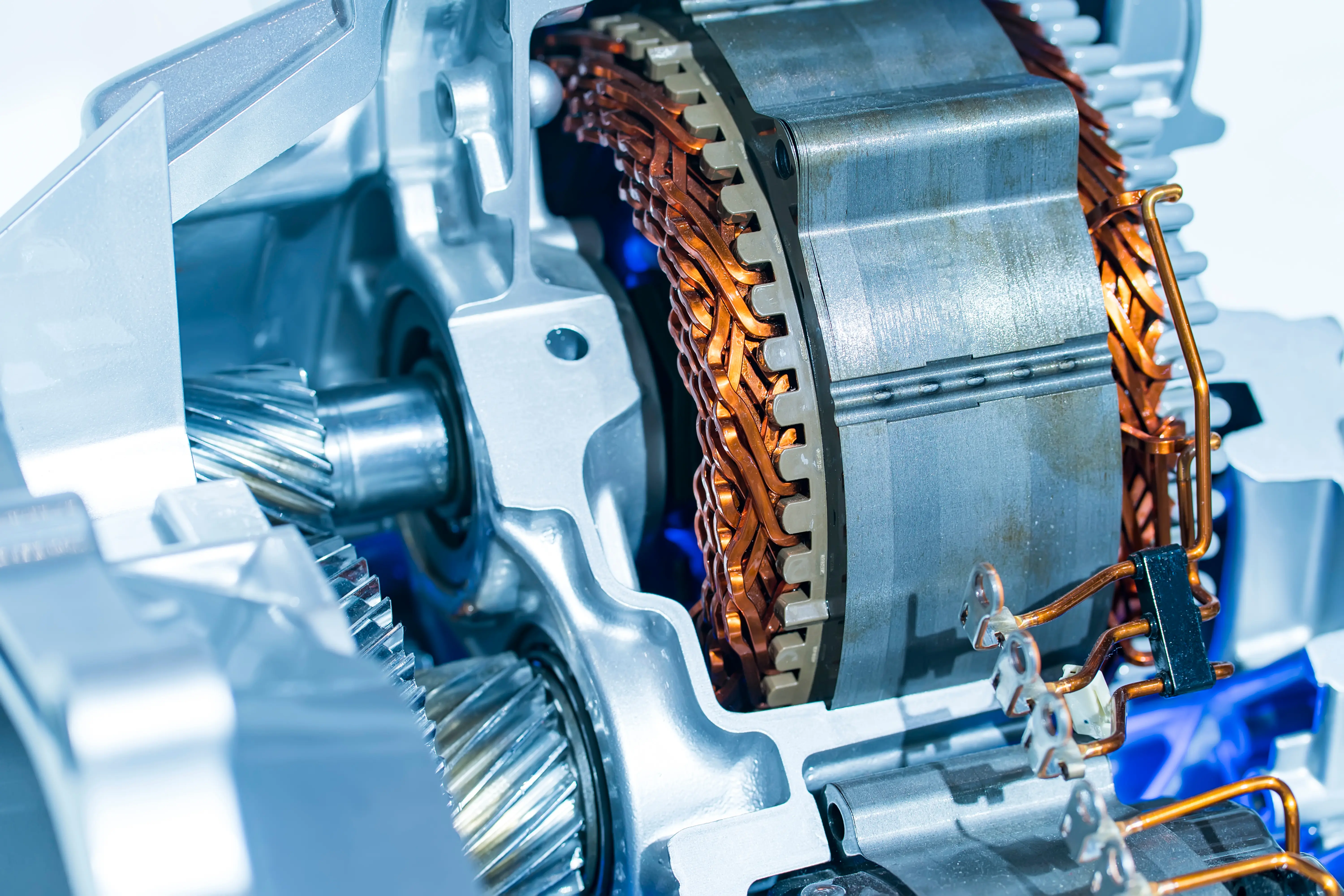

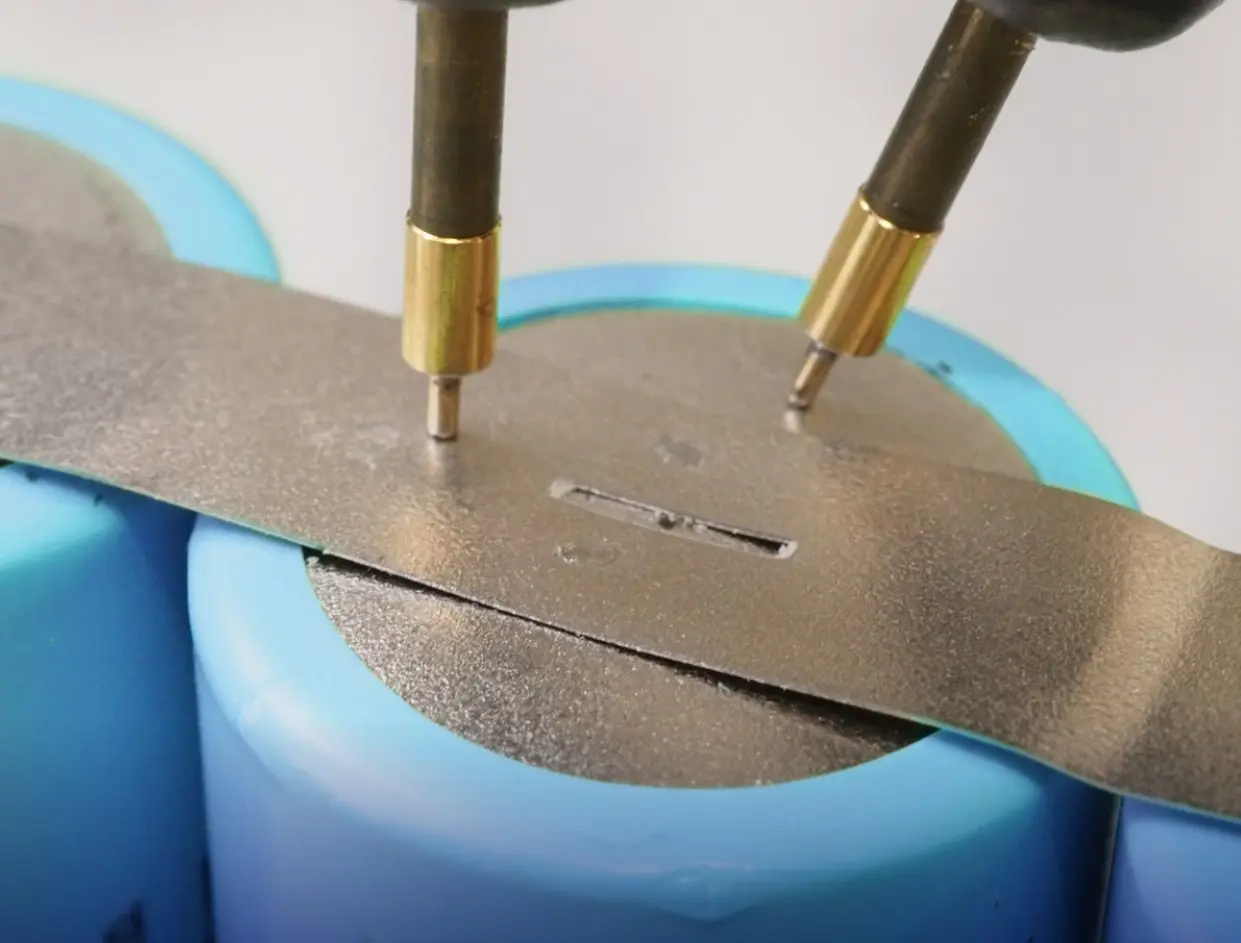

The key to efficient high-voltage batteries

To be firmly pushed back into your seat when kicking down the “accelerator pedal” in an electric sports car, the high-voltage battery pack needs to feed a high current to the electric drive motor. This in turn requires batteries that have a low resistance – and the right measurement technology.

Accurate High Voltage Power Measurement

HIOKI’s all new High Voltage Divider VT1005 is an important addition to the HIOKI power measurement solutions. In combination with one of the HIOKI power analyzers, the VT1005 enables to accurately measure power up to 5kV. Especially for high voltage and high frequency applications with SiC and GaN semiconductors, the VT1005 realizes a huge improvement in accuracy over currently available solutions. Additionally, the for loss measurement of HV coils and transformers the new VT1005 is the perfect choice because of its 4MHz bandwidth.

High Precision Current Logging. Ultra-Compact

Optimizing the energy efficiency of electrical systems remains a continuous challenge. To address this, HIOKI has designed an innovative multi-channel current measurement solution tailored specifically for development teams in the electrical and e-mobility industry. For the first time, even the smallest currents in an Electric Vehicle (EV) or other electrical systems can be measured and logged individually by using ultra-compact, high-precision current sensors. By analyzing this data, engineers can gain valuable insights and draw conclusions on how to significantly improve energy efficiency.

Phase Shift Correction: It takes two to tango

Phase shift correction in power analysis is like dancing a tango: it takes two – the power analyzer supporting the function as well as a suitable sensor with a known phase delay. If one of them is missing… well… just imagine that tango…

Measuring Ultrafast Inverters with High Precision

Power analyzers produce increasingly incorrect, even impossible, measurement results when analyzing ultrafast SiC and GaN inverters. The solution are current sensors specif-ically developed for power analysis from a single source! For the first time, HIOKI's pow-er analyzers and sensors form a 100% matched power measurement system. This ena-bles automatic phase shift correction.

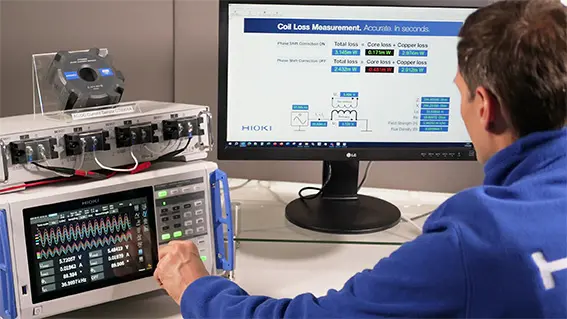

Coil loss measurement. Accurate. In seconds.

The increasing deployment of SiC and GaN semiconductors in power electronics lead to higher switching frequencies. As a result, smaller and lighter coils can be used in power converters. This also puts major challenge for measurement technology that you need to improve efficiency. Conventional power analyzers produce inconsistent and even incorrect measurement results when analyzing coil loss at the high switching frequencies. The key to easily obtain accurate and repeatable results is automatic phase shift correction. HIOKI makes this possible by perfectly synchronizing the power analyzer with our current sensors and high voltage dividers.