HIOKI RM3546 - High-precision DC resistance meter optimized for weld resistance inspection

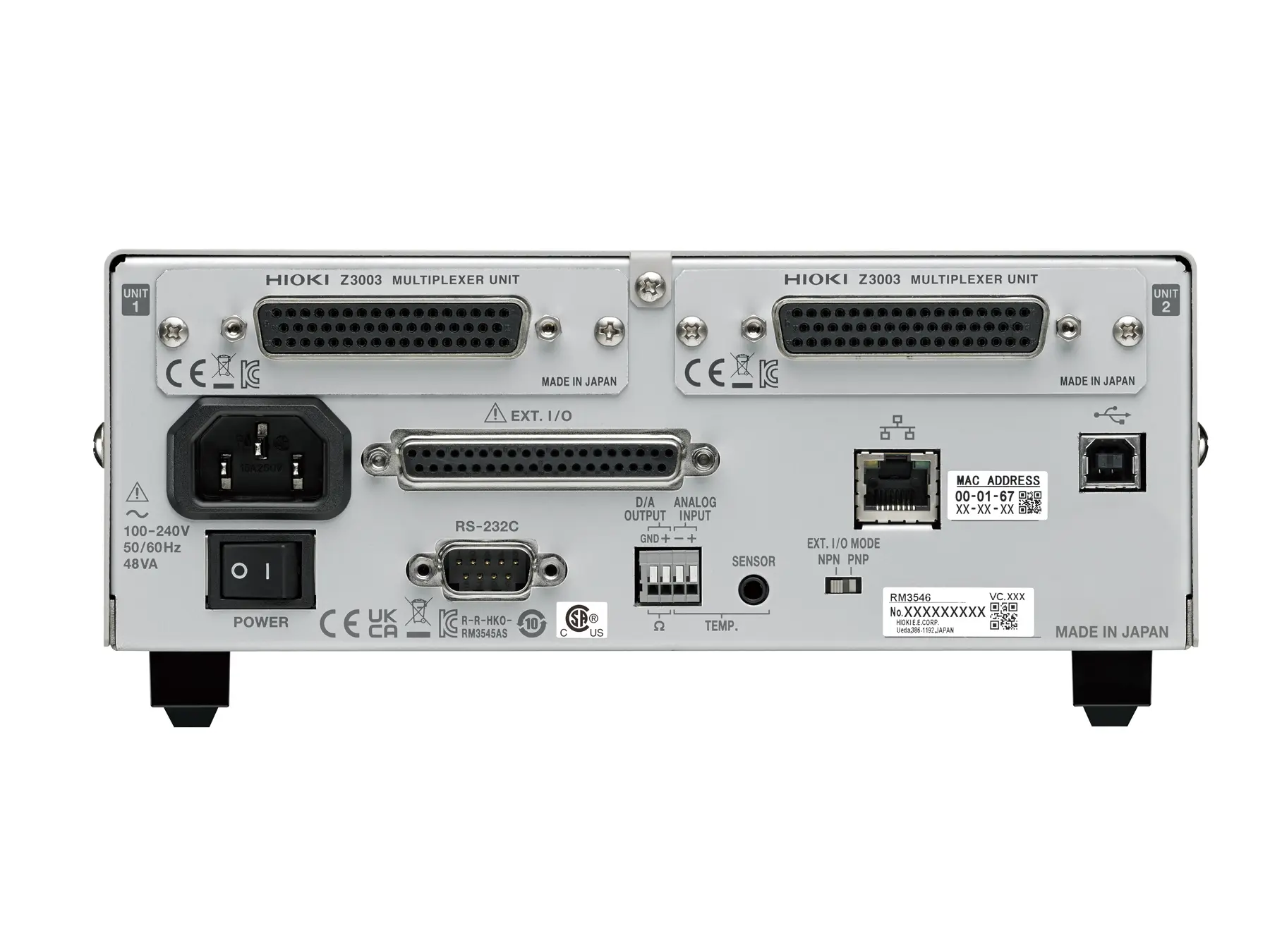

DC resistance meter with Active Circuit Protection up to DC 60 V, high path resistance tolerance, 13 ranges from 1 mΩ to 1000 MΩ, max 1 A test current, multiplexer option (up to 20 channels), remote control via LAN, RS-232C and USB

€3,388.00*

Content:

1 Each

In stock in Germany

€3,388.00*

HIOKI RM3546 - High-precision DC resistance meter optimized for weld resistance inspection

Available stock:

1

Product number:

RM3546

EAN:

4536036014903

Length:

307 mm

Width:

215 mm

Height:

80 mm

Weight:

3.5 kg

Product information HIOKI RM3546 - High-precision DC resistance meter optimized for weld resistance inspection

Key Specifications

- Resistance ranges: 1 mΩ to 1000 MΩ (13 ranges)

- Active Circuit Protection: DC 60 V

- Path resistance tolerance: up to 9 Ω (PR mode, 500 mA)

- Maximum test current: 1 A DC

- Multiplexer option with Z3003 for up to 20 measurement channels (4-wire mode)

Typical Applications

- Automated battery cell tab weld resistance inspection

- Busbar weld resistance inspection in battery modules

- Manual resistance measurement of battery module connections

- Automated multi-point resistance measurement using Z3003 multiplexer option

Detailed Product Overview

The RM3546 is a DC resistance meter optimized for weld resistance inspection on battery cells and modules. It supports stable micro-ohm measurements performed shortly after welding, while the joint is still cooling down and resistance values are affected by temperature changes, extended wiring and multiple contact interfaces along the measurement path. The instrument also incorporates Active Circuit Protection up to DC 60 V for safe manual resistance measurements during battery module service.The RM3546 offers 13 resistance ranges from 1 mΩ to 1000 MΩ with a maximum test current of 1 A. The lowest 1 mΩ range provides the resolution required for accurate evaluation of small resistance changes at welded joints, with a measurement resolution down to 1 nΩ and a basic accuracy of ±0.045% rdg ±0.010% f.s.. Optional internal multiplexer cards enable automated multi-channel resistance measurements without the need for an external scanner or additional control hardware.

Measurement stability with long cable runs

In automated test systems, the resistance meter is often installed at a distance from the measurement point. This can result from cabinet layouts, space constraints or environmental separation between the instrument and the test location. As a result, measurement setups frequently involve long cable runs and additional series elements in the measurement path.These installation-related factors increase the resistance of the measurement path and can influence low-resistance measurements. With a path resistance tolerance of up to 9 Ω, the RM3546 maintains stable micro-ohm measurements even under such conditions. This reduces dependence on cable length and wiring layout and simplifies integration into automated test systems.

Temperature effects after welding

After welding, the electrical resistance of a joint varies with temperature during the cooling phase, which can complicate the evaluation of measurement results even when the weld quality itself remains unchanged. In practice, this either requires waiting for complete cooling before measurement or incorporating the temperature at the weld location into the resistance evaluation, which in turn requires a reliable and reproducible temperature-related reference at the time of measurement.To reduce such temperature-related variations, the RM3546 provides a Temperature Compensation (TC) function. Resistance values are compensated using an externally supplied temperature signal at the time of measurement. The RM3546 accepts an analog input signal in the range of 0 to 2 V, a commonly used format for representing temperature values from suitable infrared thermometers or process sensors. The TC function can also be used to compensate ambient temperature influences when the included Z2001 Temperature Sensor is connected to the instrument.

Measurement integrity and system integration

To further support reliable low-resistance measurements under thermally and electrically unstable conditions, the RM3546 provides Advanced Offset Voltage Compensation (A-OVC). By applying the measurement current with alternating polarity and averaging the results, thermoelectric and internal offset voltages are suppressed. This enhances measurement stability under conditions such as those occurring shortly after welding. In addition, a contact-check function detects insufficient probe contact and helps reduce measurement errors caused by poor electrical connections.For automation and data acquisition, the RM3546 offers LAN, USB and RS-232C interfaces for communication with PCs and controllers, as well as an EXT I/O interface for external triggering and pass/fail signaling. An analog D/A output (0 V to 1.5 V DC) is available for monitoring or feedback control. During system setup and commissioning, the command monitor function displays communication commands and responses directly on the instrument, supporting efficient debugging and reducing integration effort.

Expandable multiplexer configuration

Two optional Z3003 Multiplexer Cards can be installed in the RM3546, each providing 10 measurement channels in 4-wire mode. When two cards are fitted, the instrument can measure up to 20 channels automatically in sequence, enabling resistance evaluation of multiple DUTs without manual reconnection. Installation requires only a Phillips screwdriver and takes about two minutes.For applications requiring more than 20 channels, the RM3546 can alternatively be combined with the HIOKI SW1002 Multiplexer System, offering up to 132 channels in 4-wire mode.

Battery contact measurements during service

In service applications, resistance measurements on battery contacts and interconnections are typically performed manually using conventional test leads. In manual measurements, one probe may contact a busbar carrying voltage while the other probe unintentionally touches the enclosure or ground. Without an appropriate protection function, such situations can result in damage to the resistance meter.For this reason, the RM3546 incorporates an Active Circuit Protection (ACP) up to DC 60 V. This function protects the instrument against unintentionally applied voltages at the measurement input and facilitates safe use in service environments. While primarily relevant for service applications, Active Circuit Protection also provides an additional layer of protection during system setup, commissioning or maintenance tasks in production environments.

- RM3546 Resistance Meter

- Power cord

- Temperature sensor Z2001

- Male EXT I/O connector

- EXT. I/O connector cover

- Start-up guide

- Operating Precautions

-

RM3545A, RM3546 Measurement Lead Selection Guide (English)1,048 KB pdf

-

Instruction Manual, RESISTANCE METER RM3545A, RM3546 (English)8,158 KB pdf

-

Instruction Manual, RESISTANCE METER RM3545A, RM3546 (Spanish)7,817 KB pdf

-

Product Catalog, Measuring Instruments for the Battery Industry (English)6,753 KB pdf

-

Datasheet, Resistance Meter RM3545A, RM3546 (English)1,987 KB pdf

-

Product brochure with datasheet, RESISTANCE METER RM3546 (English)4,089 KB pdf