CT6844A - AC/DC High-accuracy Current Clamp, 500 A / 500 kHz

AC/DC current clamp using advanced fluxgate technology, 500A rated current, basic accuracy ±0.2% rdg., wide temperature range of -40 °C to 85 °C, wide bandwidth from DC to 500 kHz, maximum conductor diameter 20 mm, cable length 3 m

€1,702.40*

% €2,128.00* (20% saved)

Content:

1 Each

In stock in Germany

Available stock:

6

Product details

Product number:

CT6844A

EAN:

4536036013883

Length:

153 mm

Width:

67 mm

Height:

25 mm

Weight:

0.4 kg

Product information CT6844A - AC/DC High-accuracy Current Clamp, 500 A / 500 kHz

Key Specifications

- AC/DC currents up to 500 A

- Frequency Bandwidth DC to 500 kHz

- Basic accuracy: ±0.2% rdg.

- Operating temperature: -40 °C to 85 °C

- Output voltage ratio 4 mV/A

Typical Applications

- WLTP testing (Worldwide harmonized Light vehicles Test Procedure)

- Evaluation of current consumption of automotive electrical components like air compressors or power steering systems

- On-site efficiency and current evaluation of inverters and motors

Detailed Product Overview

The current clamp delivers reliable performance across a wide temperature range of -40 °C to 85 °C, ensuring stability even in demanding environments such as engine compartments and outdoor testing locations. It is well-suited for evaluating the current consumption of automotive electrical components, including air compressors and power steering systems. Additionally, its high-accuracy clamp design allows for efficient on-site assessment of IGBT inverters (Insulated Gate Bipolar Transistors) and motor performance. Technicians can use it to conduct precise efficiency evaluations and current measurements, enabling them to quickly identify anomalies or performance degradation, ultimately supporting effective maintenance and diagnostics.

Phase shift correction functions of HIOKI Power Analyzers are supported, including the automatic correction feature of the PW8001 Power Analyzer. By integrating these features, it ensures accurate power analysis in dynamic and high-frequency applications, minimizing measurement errors and enabling higher precision in power evaluation.

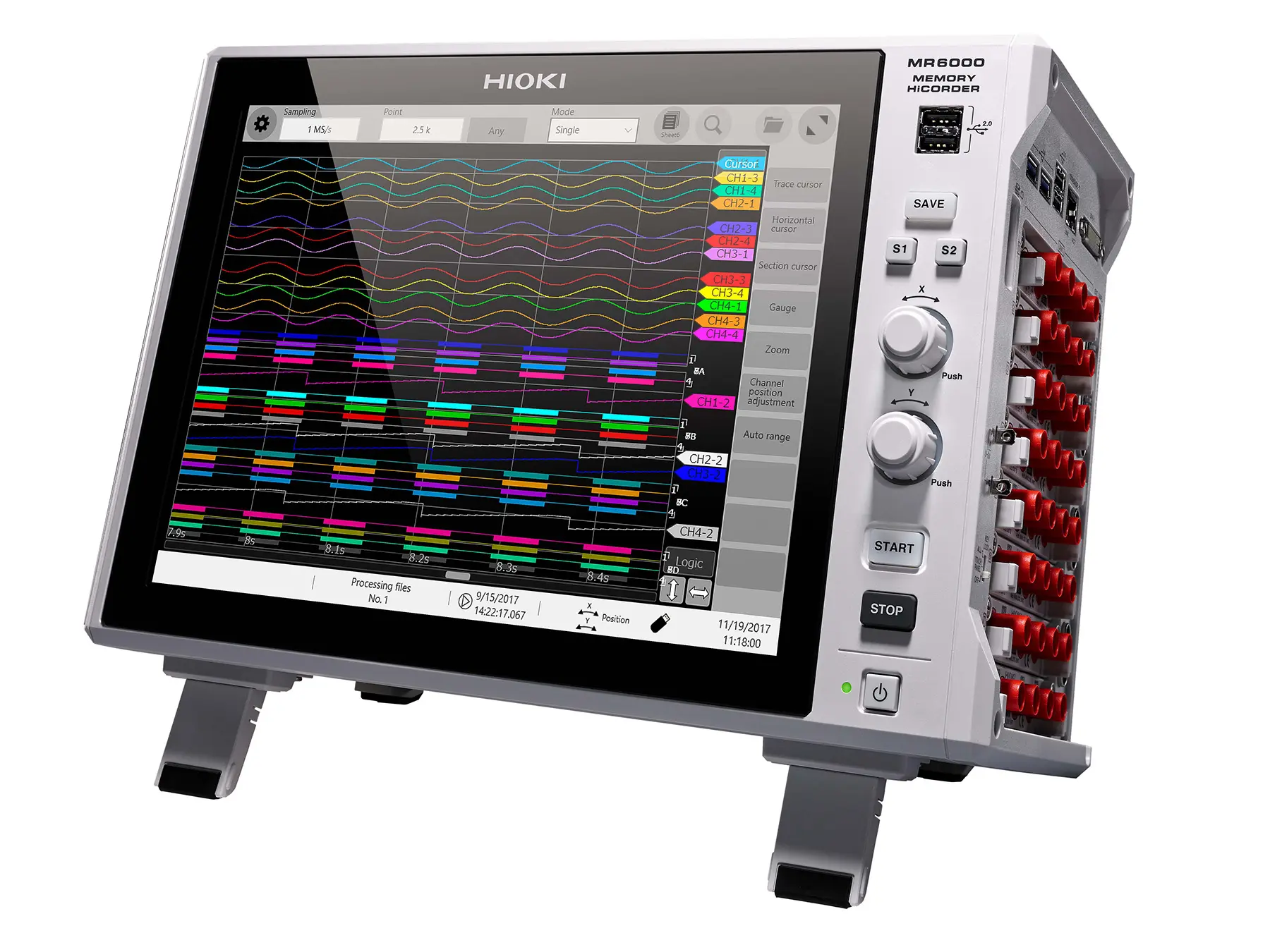

Direct connection to HIOKI Power Analyzers and Memory Recorders is possible via the ME15W connector, which also supplies power to the CT6844A. Additionally, when combined with a HIOKI sensor unit (CT9555, CT9556, CT9557), it can be used with oscilloscopes and other data acquisition (DAQ) systems, providing a voltage output ratio of 4 mV/A. Furthermore, its robust construction, 20 mm core diameter, and 3-meter cable length allow for flexible installation in various test environments.

The CT6844A is an essential tool for high-precision current measurement, including WLTP testing (Worldwide harmonized Light vehicles Test Procedure). With a durable design, precise fluxgate technology, and adaptability to various operating environments, it provides reliable measurement performance across both laboratory and field applications.

Zero-flux Current Clamps: Accuracy without effort from mA to kA

- Carrying Case

- Markup bands ×6

- Instruction Manual

-

Product catalog with data sheet, current sensors & current probes series (English)15,061 KB pdf

-

Product brochure with data sheet, Sensor Unit CT9555, CT9556, CT9557 (English)1,693 KB pdf

-

Product catalog, POWER ANALYZER Series (English)2,717 KB pdf

-

Product Catalog, Power Meter Series PW3335, PW3336, PW3337, 3333, 3334 (English)9,156 KB pdf

-

Instruction Manual, AC/DC CURRENT PROBE CT6844A (English)1,299 KB pdf