SP9200 - Screw-type probes for SP7001 CAN-FD Sensor

Screw-type probes for use with the SP7001 CAN-FD Sensor, set of two probes

€908.00*

Content:

1 Each

In stock in Germany

€908.00*

SP9200 - Screw-type probes for SP7001 CAN-FD Sensor

Available stock:

1

Product number:

SP9200

EAN:

4536036012398

Length:

217 mm

Width:

60 mm

Height:

158 mm

Weight:

0.14 kg

Product information SP9200 - Screw-type probes for SP7001 CAN-FD Sensor

Detailed Product Overview

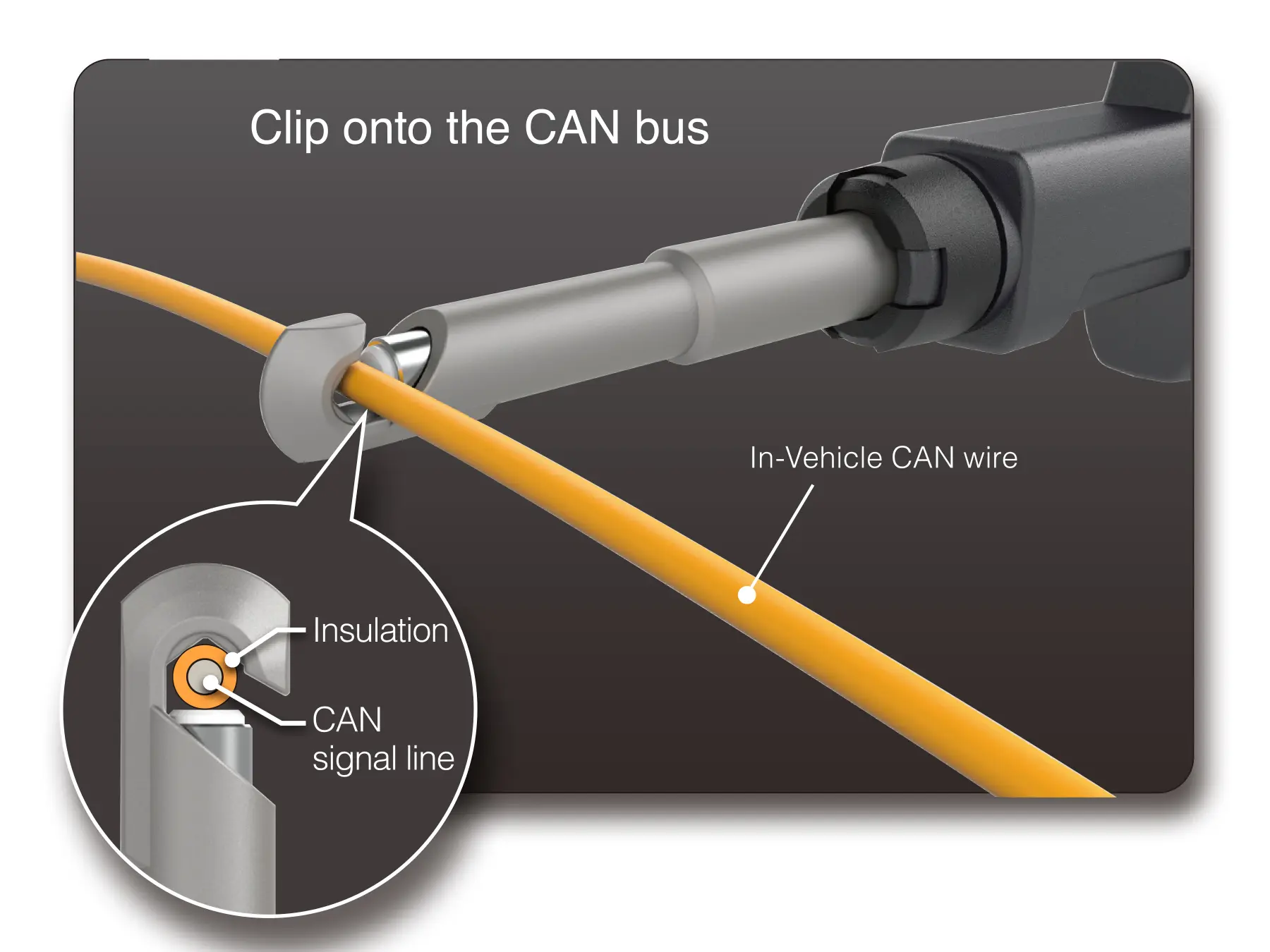

The HIOKI SP9200 Screw-type Probe Set is designed for use with the SP7001 CAN-FD Sensor and the SP7100 or SP7150 CAN Interface to enable non-contact detection of CAN or CAN FD signals through the cable insulation. Using capacitive coupling, the two probes together detect the differential signal through the insulation of the CAN H and CAN L lines, without requiring direct electrical contact or wire modification.The screw-type clamping mechanism allows the probes to be firmly fixed to the insulated CAN wires, ensuring a stable capacitive connection even under vibration or mechanical stress. This design makes the SP9200 ideal for long-term or in-vehicle measurements, where durability and signal stability are essential.

Each set contains two probes, corresponding to one CAN bus (CAN H and CAN L). When combined with the SP7001 CAN-FD Sensor and a compatible interface, the SP9200 enables reliable, non-intrusive monitoring of CAN or CAN FD communication under real operating conditions.

Designed for operation from -40 °C to +85 °C, the SP9200 provides a robust and vibrationresistant solution for contactless acquisition of CAN and CAN FD signals in automotive development and validation environments

- SP9200 Screw Type Probe Set