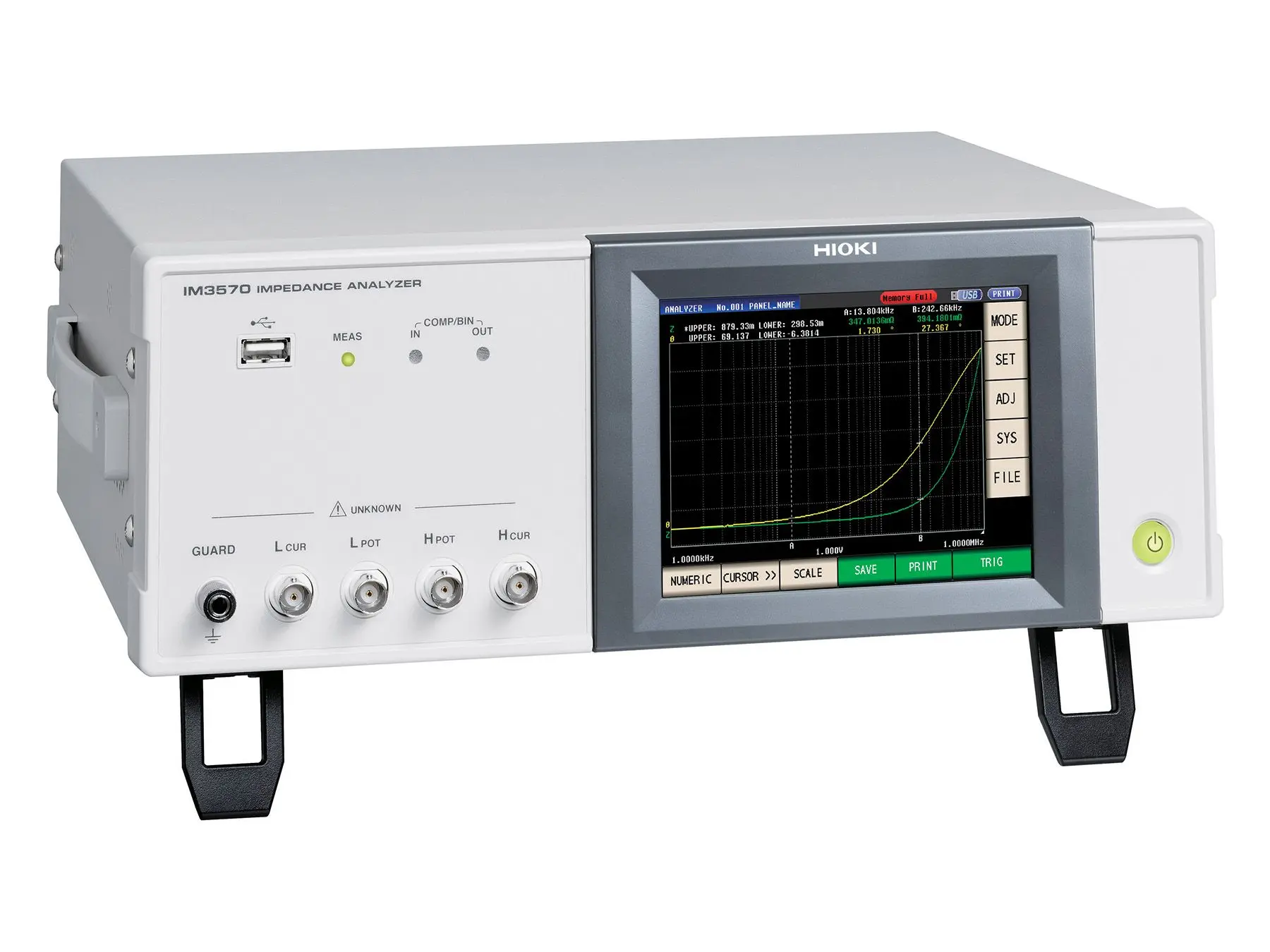

HIOKI LCR Meters and Impedance Analyzers

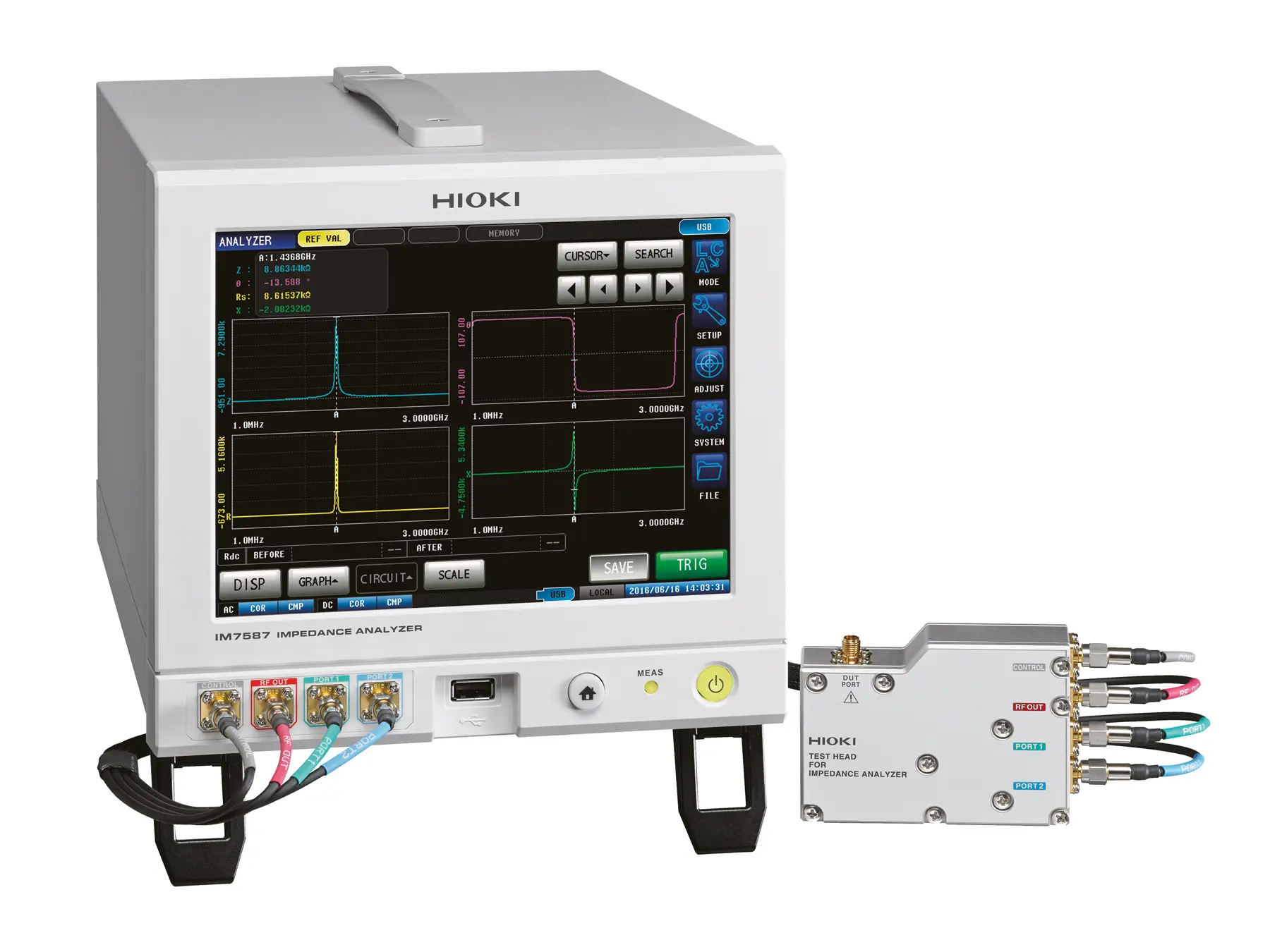

1 mHz to 3 GHz impedance testing

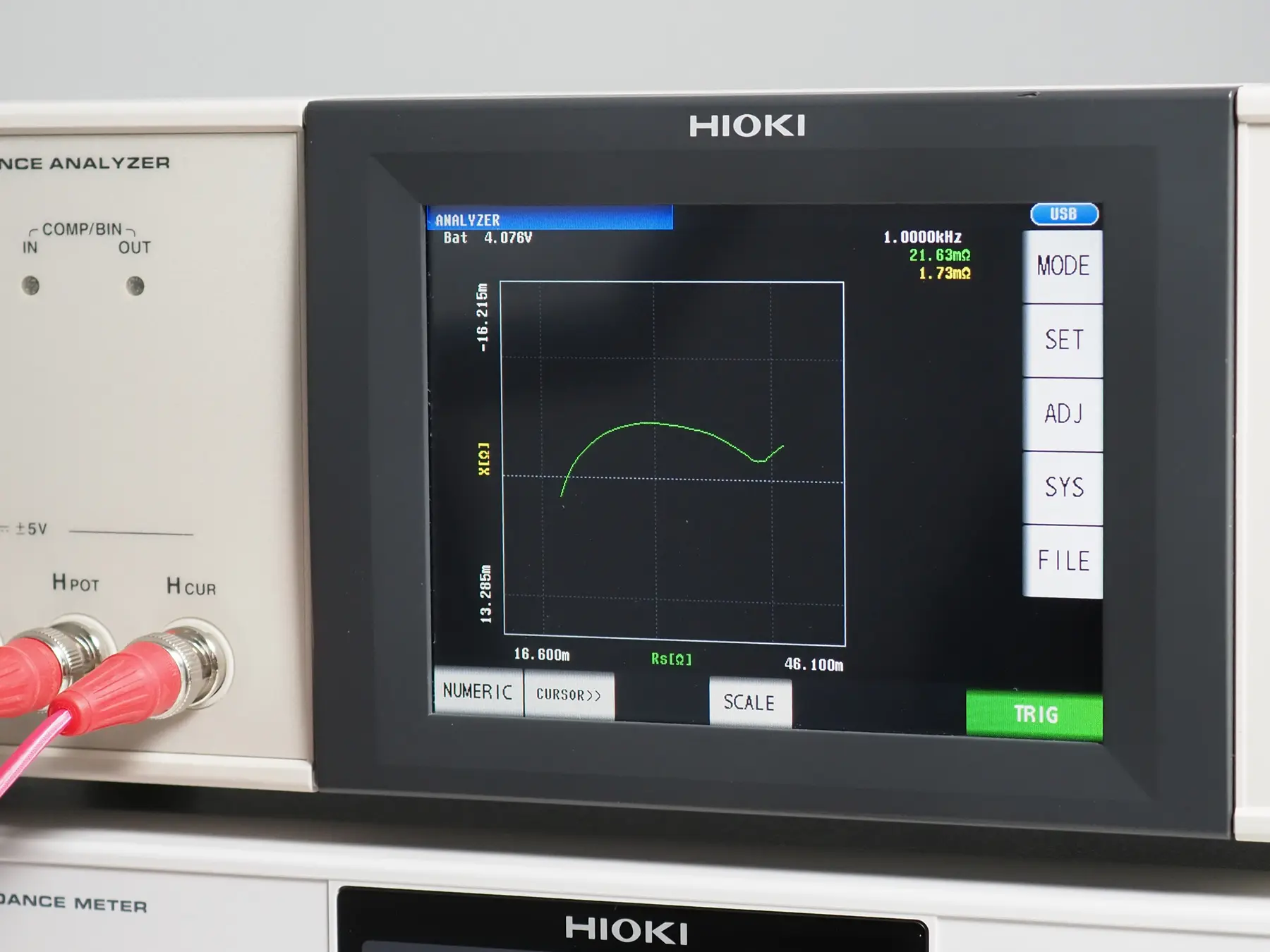

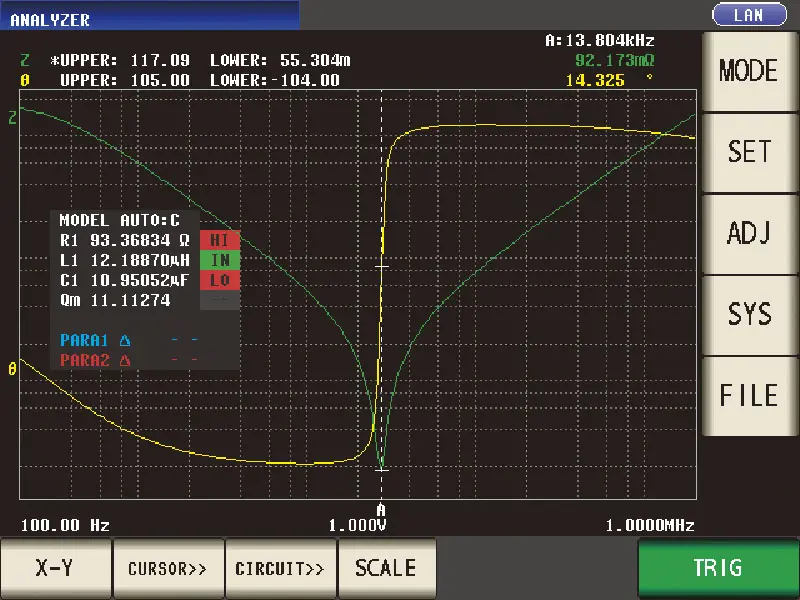

HIOKI’s LCR meters and impedance analyzers cover a wide range of applications in R&D, production, and quality control, from electrochemical impedance spectroscopy and measurements of capacitors, inductors, and transformers to SMD component testing at RF frequencies.

Fast measurement times, sweep functions, and comparator/BIN capabilities support both laboratory use and automated production environments, with all instruments designed and manufactured in Japan.

Select your instrument, from electrochemical to RF, and everything in between.