HIOKI Battery Testers for R&D and Production

Battery Test Solutions from Cell to Pack

Since pioneering the world’s first lithium-ion battery tester in 1986, HIOKI has set the benchmark in battery testing technology. Today, the BT356xA series is the de facto standard for quality control in production and development facilities worldwide. It delivers reliable resistance and voltage measurements to ensure battery reliability.

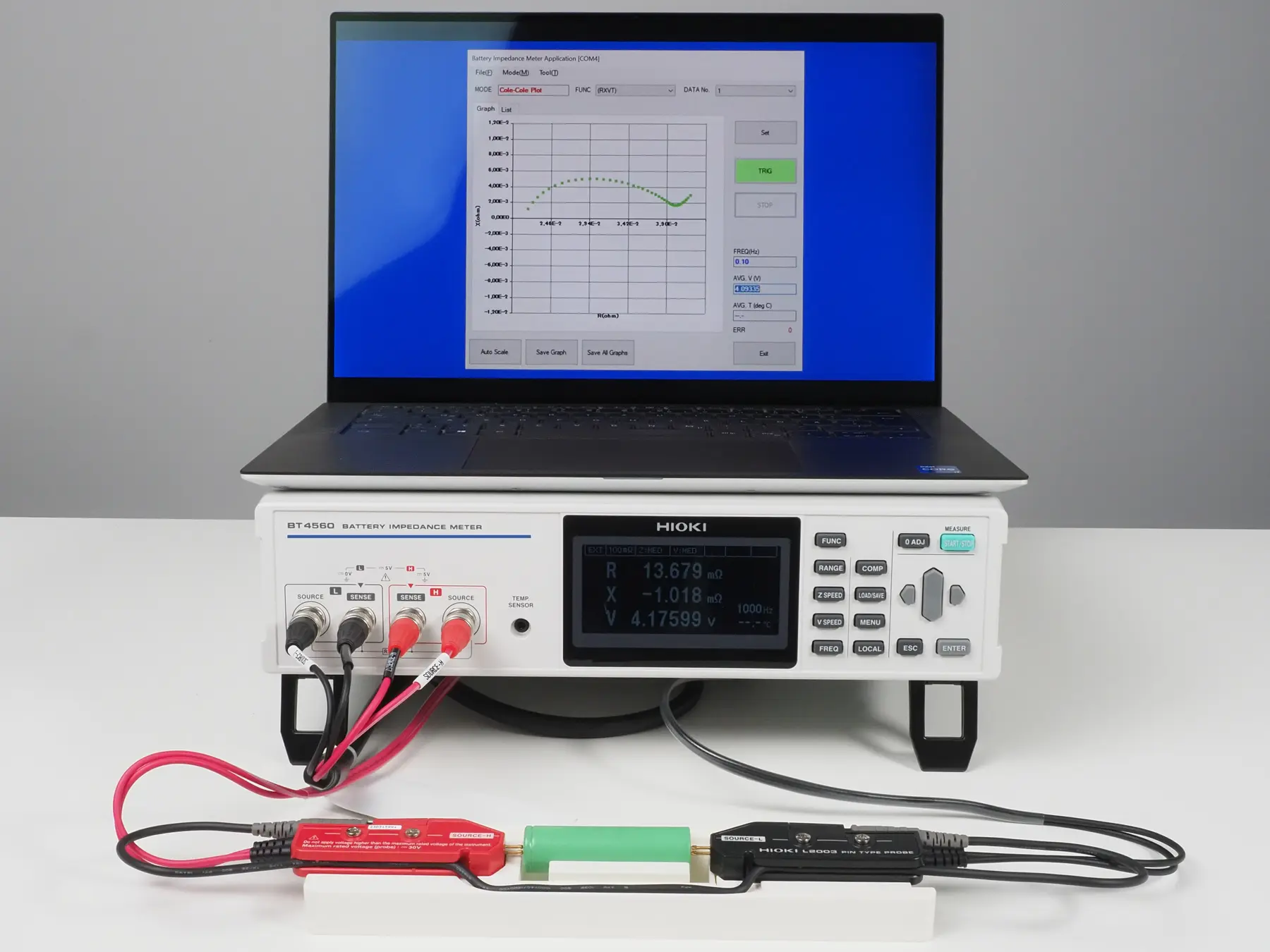

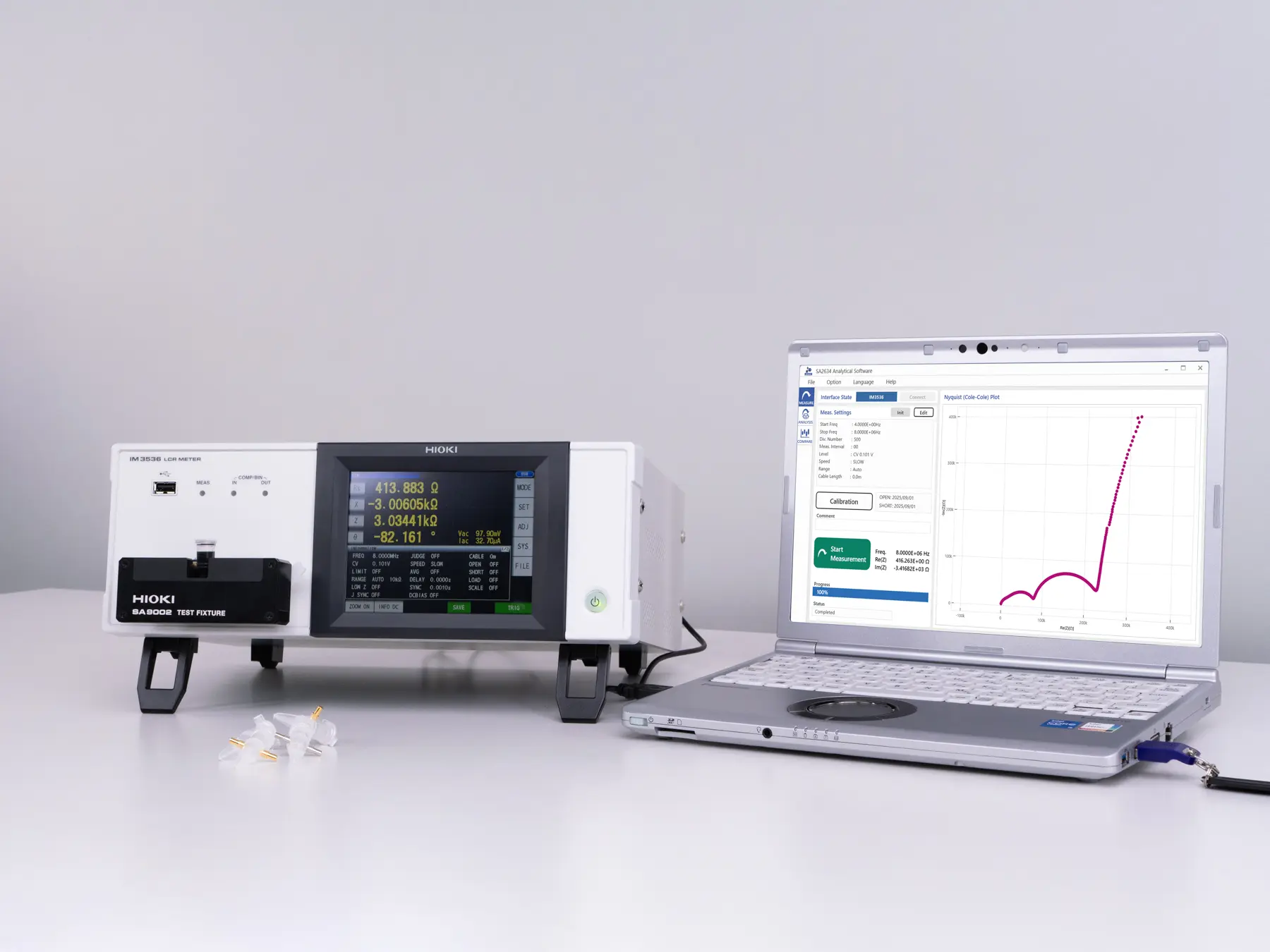

For high-voltage battery packs, the BT3564 supports testing up to 1000V. Meanwhile, the BT4560-50 Battery Impedance Meter enables ultra-precise micro-ohm-level resistance measurements for advanced cell evaluation.

The BT6065 and BT6075 offer a 2-in-1 solution, combining simultaneous measurements of internal resistance and voltage. This ensures efficient and accurate cell grading and quality assurance during battery production.

Find the perfect solution for your battery testing needs today!