- Higher Frequencies – Smaller Inverters

- The Lower the Power Loss, the Higher the Energy Efficiency

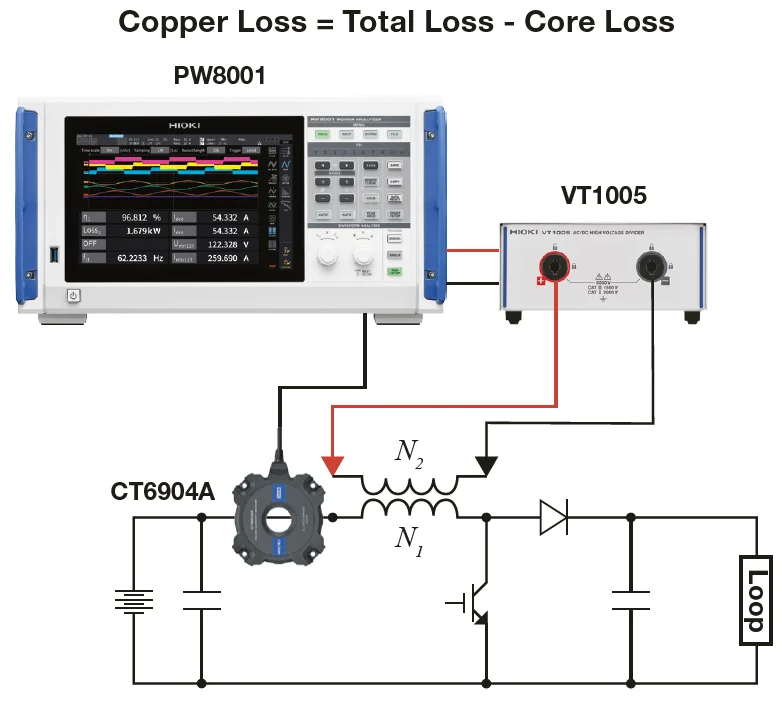

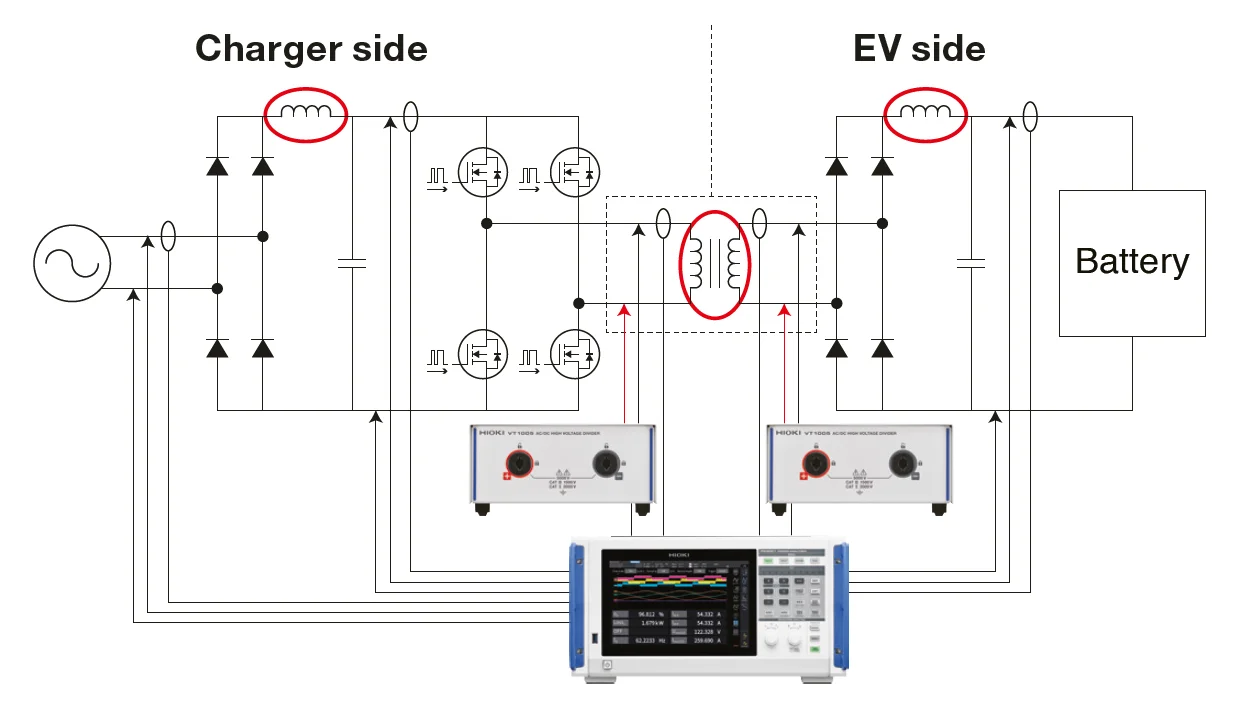

- The Two-Coil loss measurement with a power analyzer

- Accurate coil loss measurement

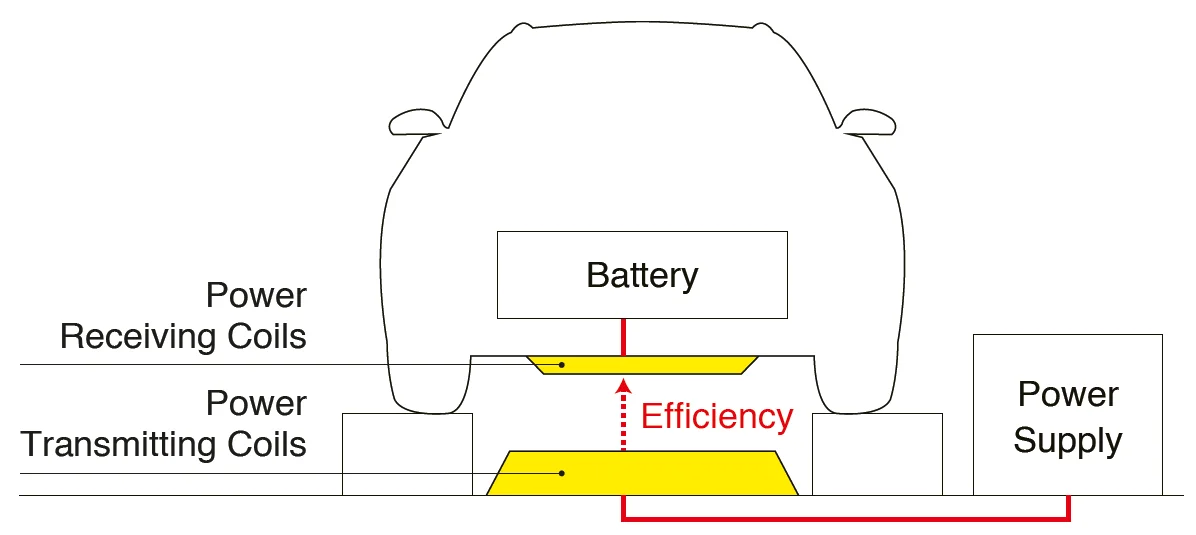

- EVs Will Soon Be Charged Wirelessly

- The solution: Accurate Coil Loss Measurement in Seconds

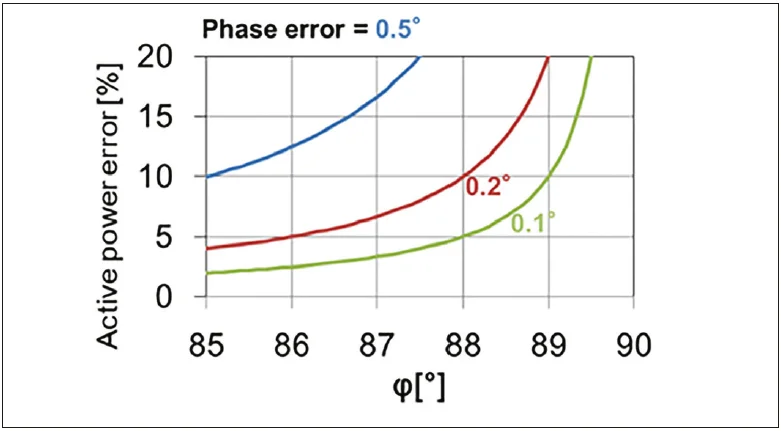

- Beyond 10 kHz, conventional power analyzers measure inaccurately

- Unique: Automatic Phase Shift Correction minimizes errors

- The ideal route to maximum precision

Power Analysis for High-Frequency Applications

The increasing use of SiC and GaN semiconductors in power electronics lead to higher switching frequencies. As a result, smaller and lighter coils can be used in power converters. This also puts major challenge for measurement technology that you need to improve efficiency. Conventional power analyzers produce inconsistent and even incorrect measurement results when analyzing coil loss at the high switching frequencies. The key to easily obtain accurate and repeatable results is automatic phase shift correction. HIOKI makes this possible by perfectly synchronizing the power analyzer with our current sensors and high voltage dividers.

Higher Frequencies – Smaller Inverters

The Lower the Power Loss, the Higher the Energy Efficiency

The Two-Coil loss measurement with a power analyzer

Accurate coil loss measurement

EVs Will Soon Be Charged Wirelessly

The solution: Accurate Coil Loss Measurement in Seconds

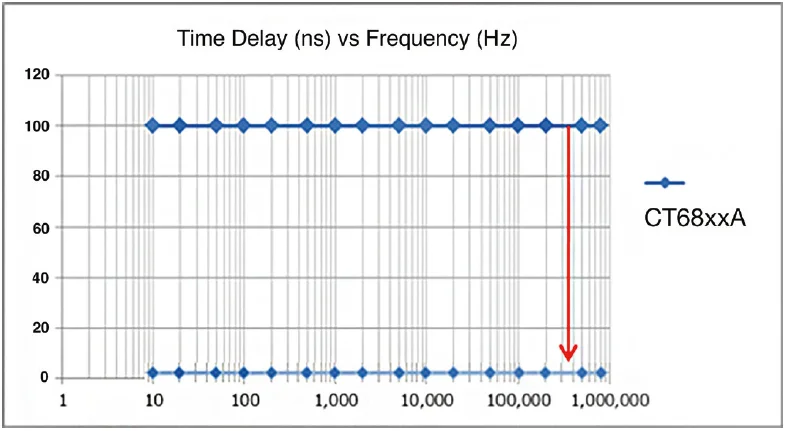

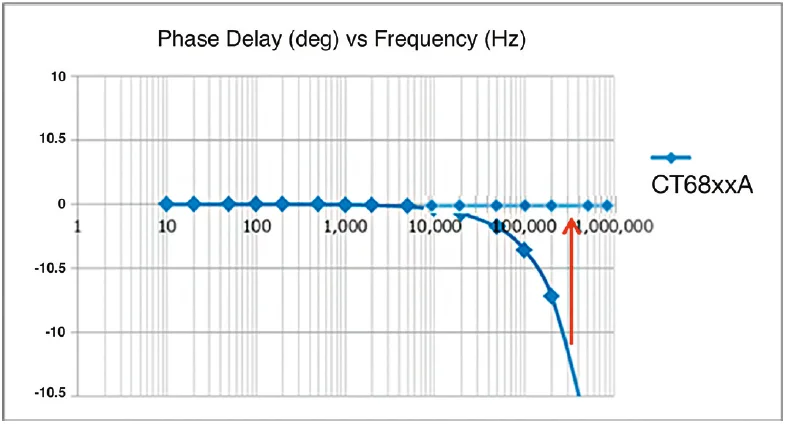

Beyond 10 kHz, conventional power analyzers measure inaccurately

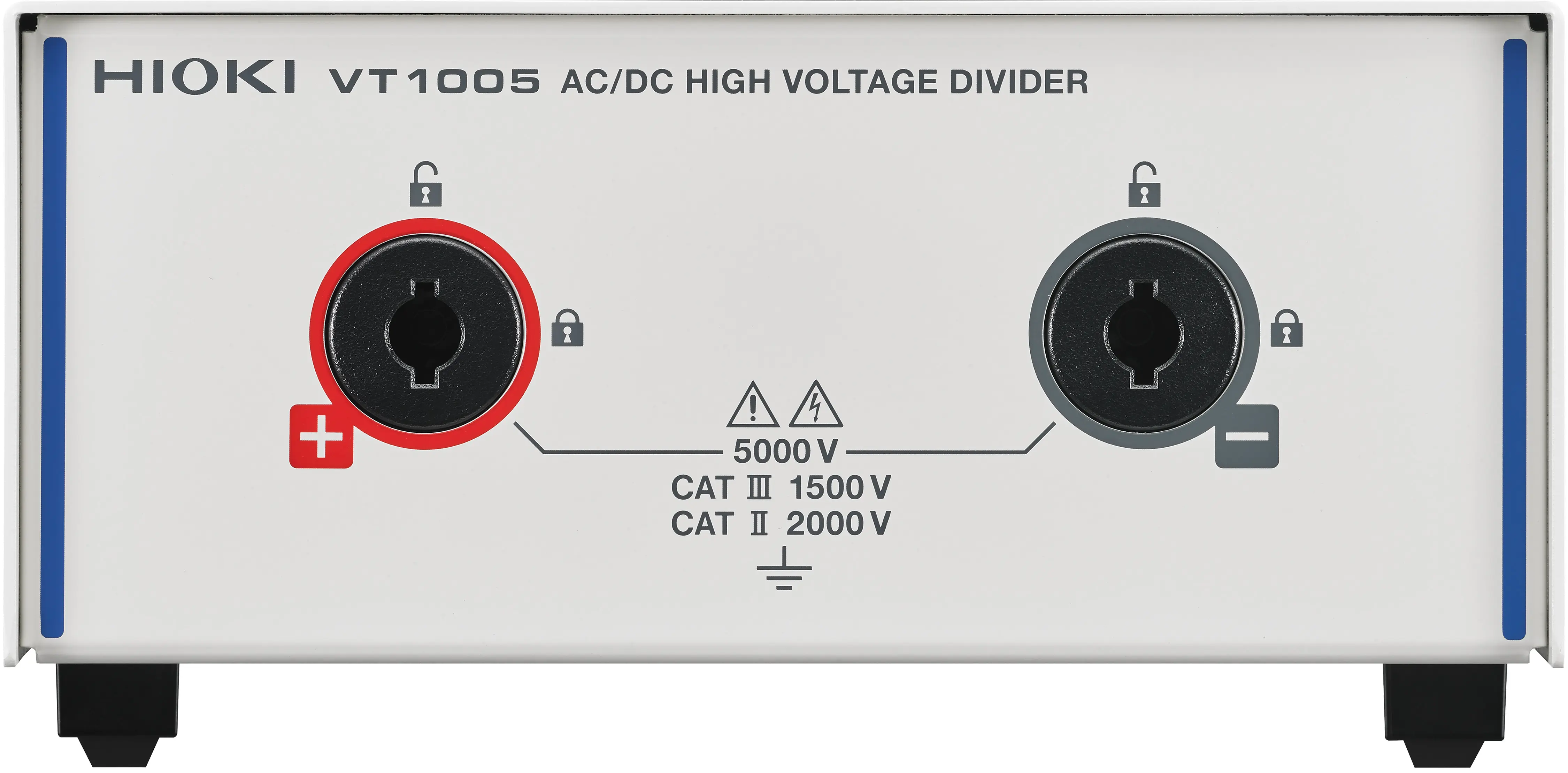

Unique: Automatic Phase Shift Correction minimizes errors

- a power analyzer that performs phase correction correctly,

- a zero-flux current sensor with a known time delay.

The ideal route to maximum precision