Z1007 - Battery Pack for LR8450 Series

The Z1007 is a lithium-ion battery pack for data loggers and wireless logger modules of the HIOKI LR8450 series.

€168.00*

Content:

1 Each

In stock in Germany

€168.00*

Z1007 - Battery Pack for LR8450 Series

Available stock:

8

Product number:

Z1007

EAN:

4536036001590

Length:

72 mm

Width:

39 mm

Height:

21 mm

Weight:

0.105 kg

Product information Z1007 - Battery Pack for LR8450 Series

The batteries charge while installed in the data logger or one of the wireless modules. If a wireless module is powered via an AC adapter and the power supply is interrupted during a measurement, the wireless module will automatically switch to battery power.

The LR8450 and LR8450-01 data loggers can be equipped with either one or two Z1007 battery packs, while each wireless logger module requires one Z1007. Installing one Z1007 in a logger provides approximately 2 hours of measurement time on battery power, depending on the number of connected modules. Using two Z1007 packs roughly doubles the runtime to around 4 hours.

When a Z1007 is installed in a wireless logger module, the approximate runtimes are as follows:

- LR8530: 9 hours

- LR8531: 7 hours

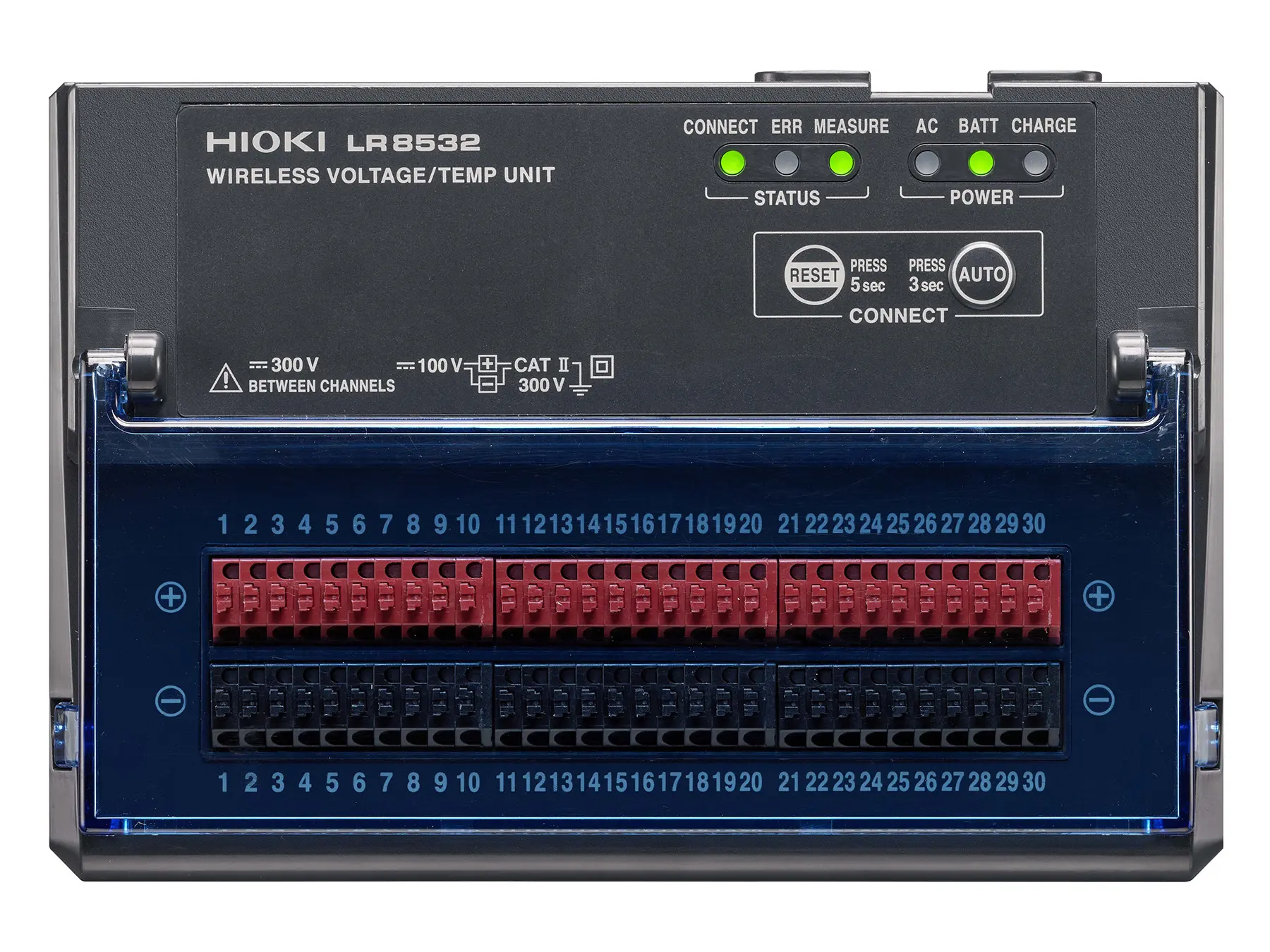

- LR8532: 9 hours

- LR8533: 9 hours

- LR8534: 5 hours

- LR8535: 10 hours (5 hours when using two non-contact CAN sensors)

- LR8536: 5 hours

Technical details:

- Battery type: Lithium ion

- For use with: LR8450, LR8450-01, LR8530, LR8531, LR8532, LR8533, LR8534, LR3535, LR8536

- Replacement battery for: LR8410, LR8510, LR8511

Measure, Analyze & Optimize Current Consumption

- Z1007 Battery Pack