IM9906 - 7 mm (APC-7) to 3.5 mm Adapter

Adapter for connecting 7 mm (APC-7) accessories to 3.5 mm measurement interfaces

€598.00*

Content:

1 Each

€598.00*

IM9906 - 7 mm (APC-7) to 3.5 mm Adapter

Product number:

IM9906

EAN:

4536036002610

Weight:

0.07 kg

Product information IM9906 - 7 mm (APC-7) to 3.5 mm Adapter

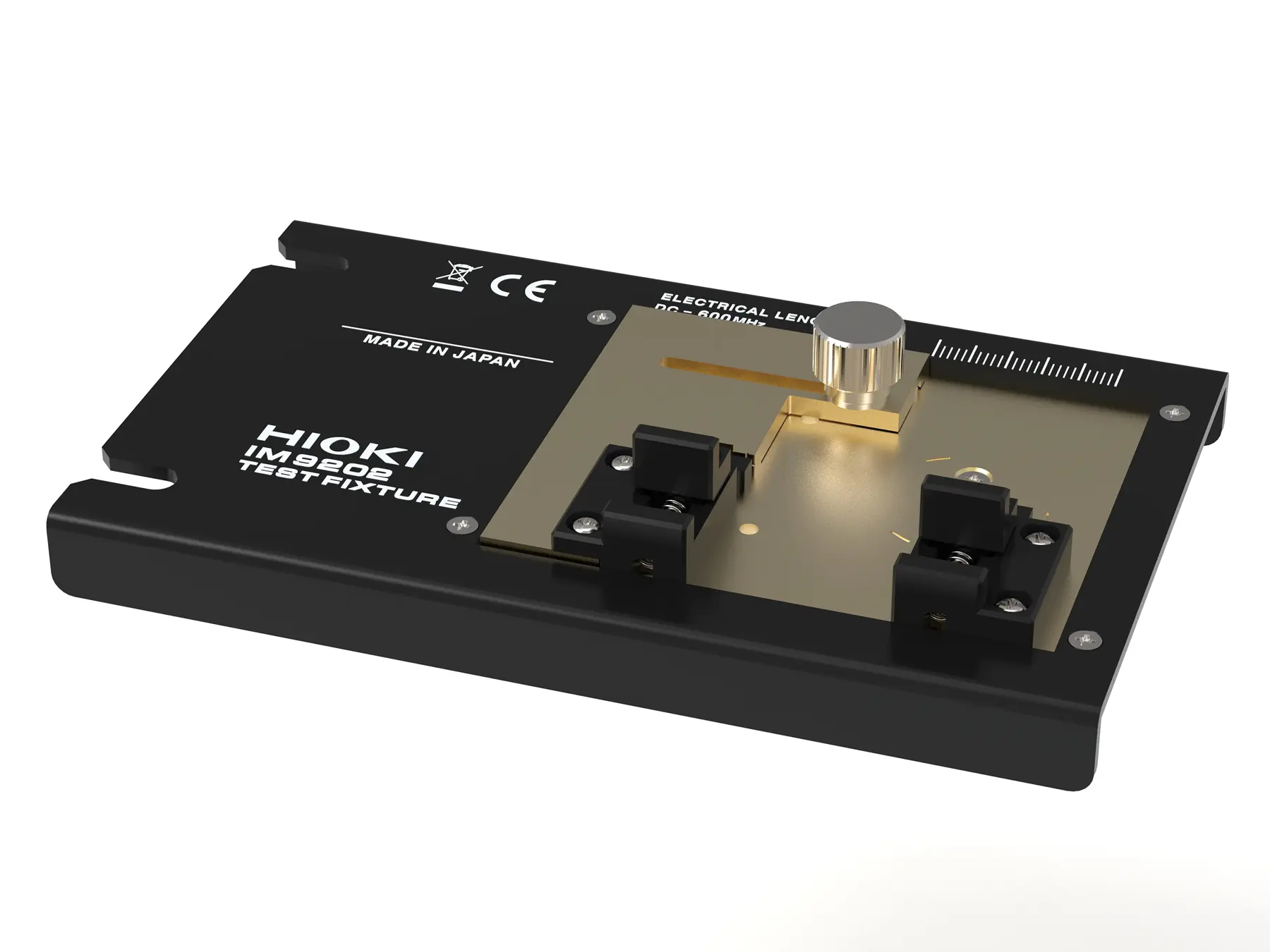

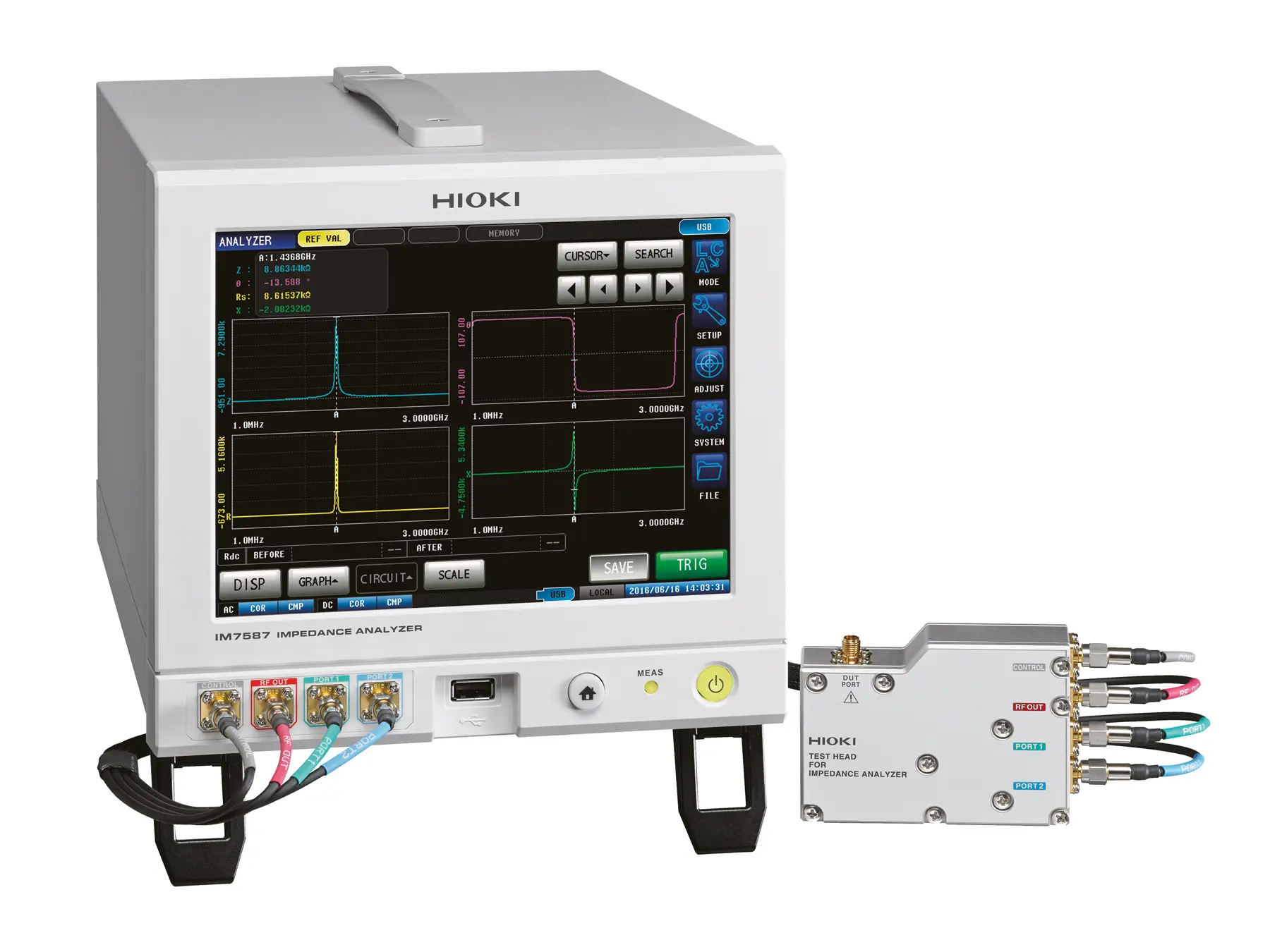

The IM9906 adapter features a 7 mm (APC-7) connection on one side and a 3.5 mm male

connector on the other side. It is used to connect 7 mm calibration standards or test fixtures

to measurement systems with a 3.5 mm test head, including HIOKI impedance analyzers

such as the IM7587, IM7585, IM7583 and IM7581.

The 7 mm (APC-7) interface is commonly used in high-frequency metrology for calibration

standards and impedance test fixtures. The 3.5 mm interface is a precision coaxial connector

used for RF and impedance measurements and is mechanically compatible with SMA

connectors, but differs in construction by using an air dielectric instead of a solid dielectric.

- IM9906 Adapter