Back to the Future: The story continues...

"Compensating flux (to zero)" is basically what a zero-flux current sensor does, and even though the magic component originally is called "flux capacitor", I stuck to the original thought and created the first part of the article with that iconic DeLorean as title picture.

In that first part you can find the technical explanation why a zero-flux current sensor has that name. HIOKI has three different types of zero-flux current sensors in the portfolio, and to explain the principle, I used the least relevant one: that's the one where low frequencies are detected with a second coil called "detection coil", and which therefore allows sensors based on this principle to only measure AC currents.

The two much more relevant zero-flux current sensor technologies are the ones that allow for the measurement of both AC and DC currents. In that case, DC and low frequencies are detected either with a fluxgate or a hall element.

Hall Element based Zero-Flux sensors

Fig. 1: HIOKI's CT6711 Zero-Flux current probe works with a Hall Element

Zero-Flux current sensors which use a hall element typically offer impressive bandwidths and come with a BNC output, making them ideal for observing current waveforms with an oscilloscope. In case of HIOKI's flagship model CT6711 the sensor's bandwidth is 120MHz, with maximum AC/DC input currents ranging from 500mA and 5A to 30A in three selectible ranges. If you wonder why and when bandwidth is relevant for a current sensor then you can find the answer in this article.

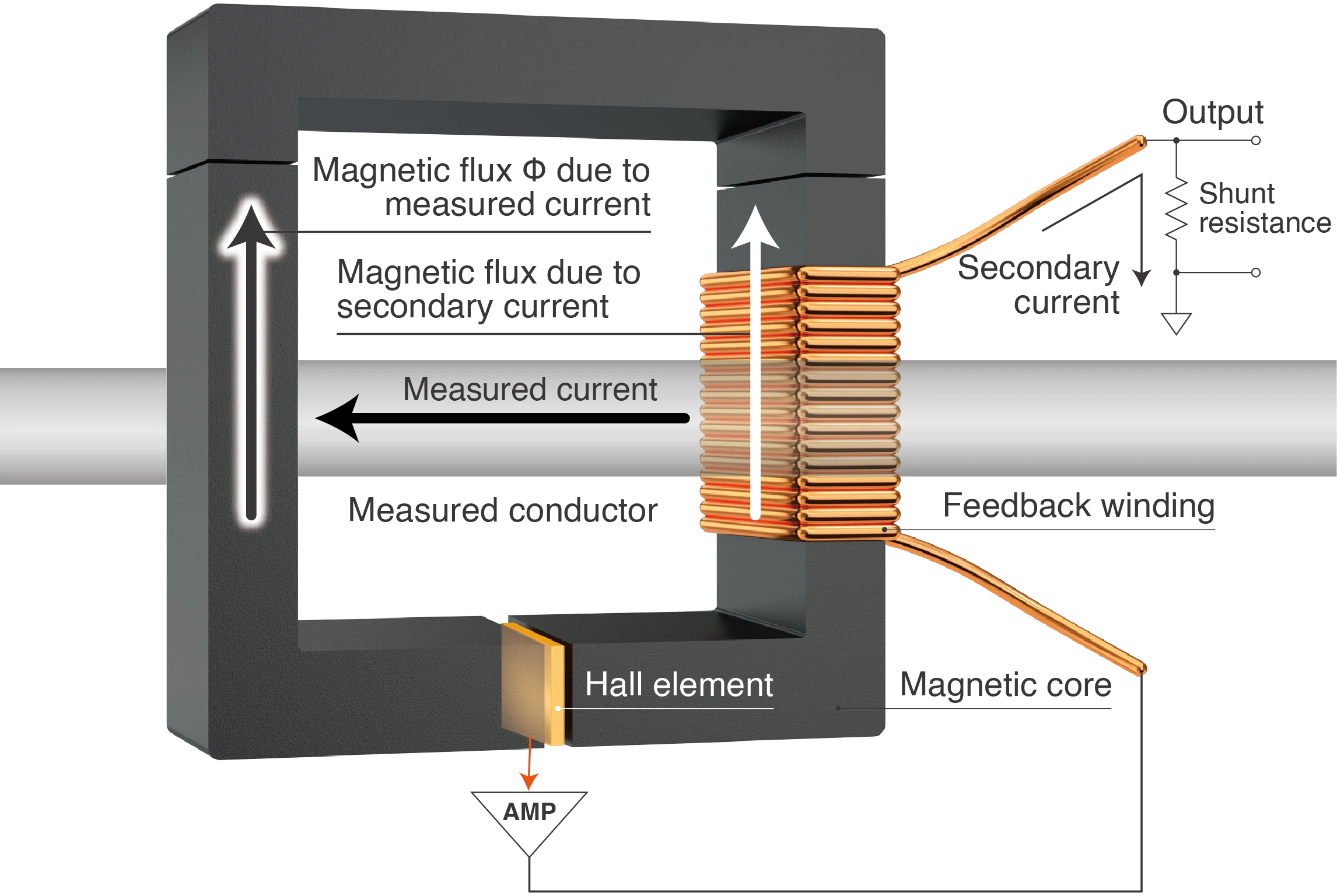

Fig. 2: Principle of Zero-Flux current sensor with Hall Element

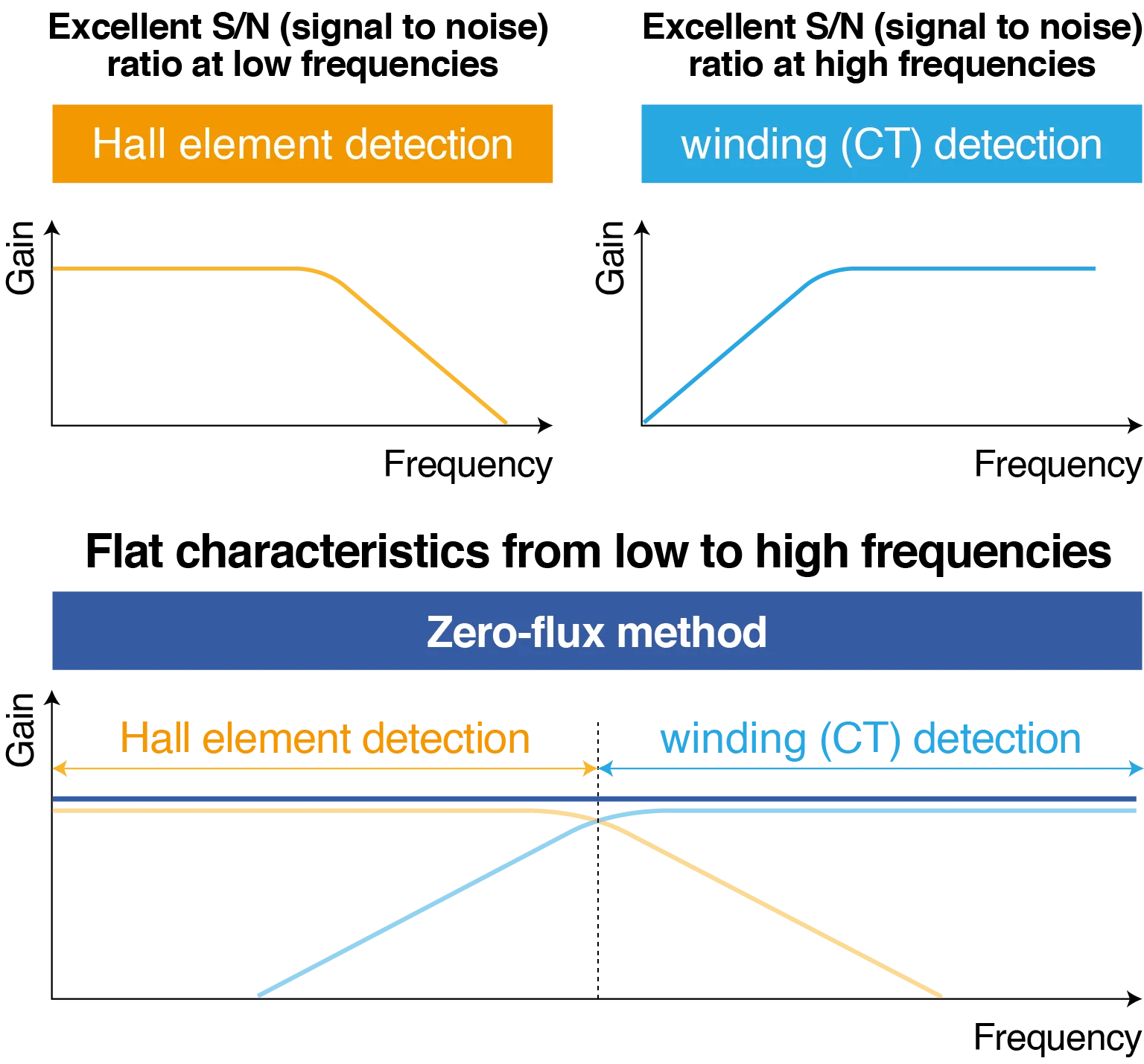

Like with all Zero-Flux current sensors from HIOKI, the hall element based sensor also uses two current detection mechanisms: the hall element for DC and lower frequencies as well as a traditional current transducer feedback coil for the higher frequencies. Since hall elements only produce a very small voltage when detecting current, an amplifier is required before feeding the signal into the feedback coil which is used to detect the higher frequencies.

Fig. 3: Two current sensing principles are used for flat sensor characteristics

Fluxgate based Zero-Flux current sensors

Fig. 4: HIOKI's CT6904 Zero-Flux current sensor uses a fluxgate

If a very high measurement accuracy is required then zero-flux current sensors with a fluxgate for low-frequency measurements are the best sensor option. Clamp / probe versions of this sensor types feature reading accuracies of 0.2% while the pass-through versions like the above pictured CT6904 offer reading accuracies of just 0.025%. The reason for the difference in accuracy of clamp and push-through versions is the core element which is split in the clamp version.

Fig. 5: HIOKI CT6844A Zero-Flux current clamp with fluxgate

A main application where these high accuracies are required is in power analysis. HIOKI fluxgate based zero-flux sensors are perfect for this task as they not only offer a very high gain accuracy but also an extremely good phase accuracy over a very wide bandwidth. In addition, these sensors provide an excellent temperature stability - which is important as power measurements can take place over a longer period of time. You can find out more about temperature drift of current sensors in this article.

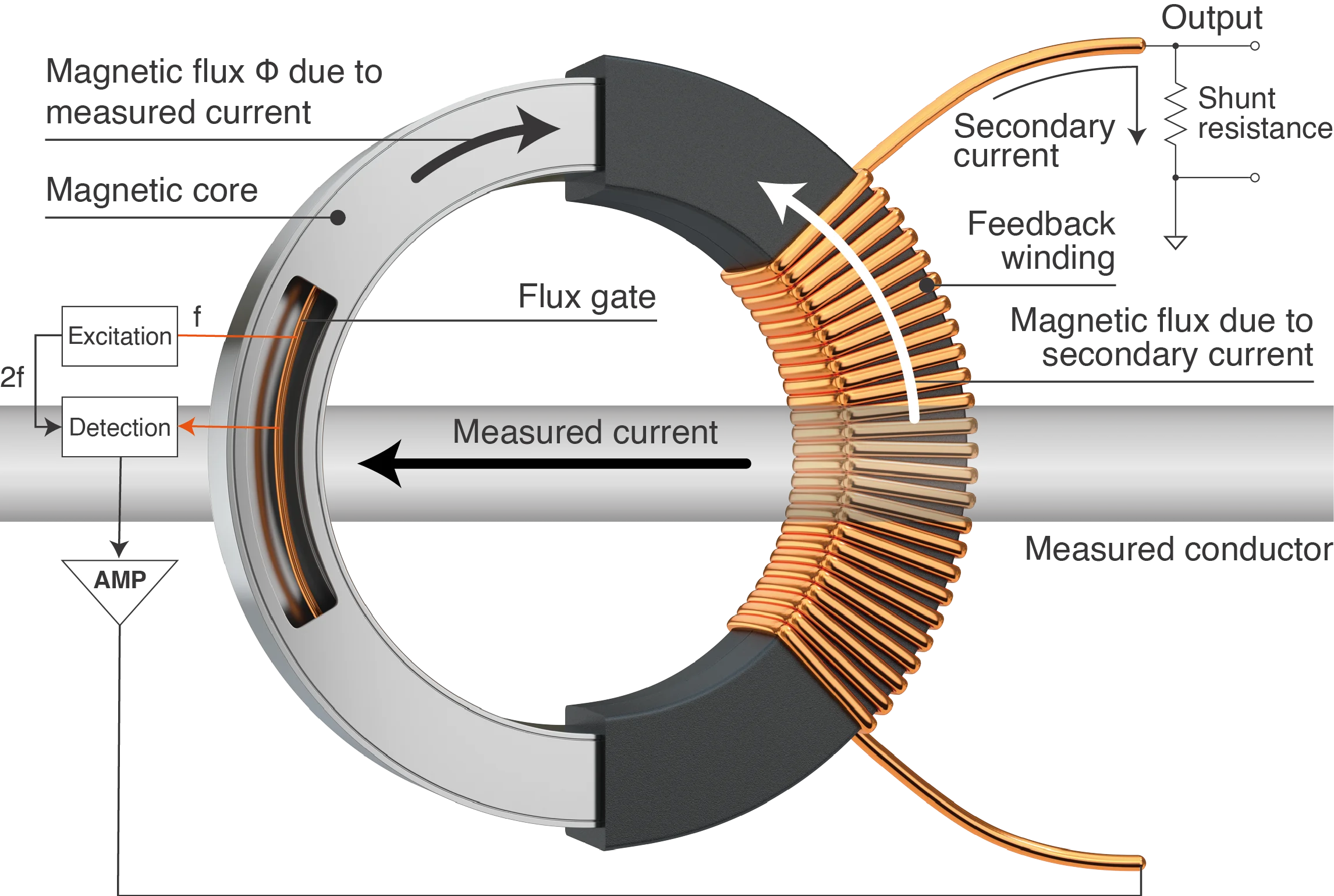

Fig. 6: Principle of Zero-Flux current sensor with Fluxgate

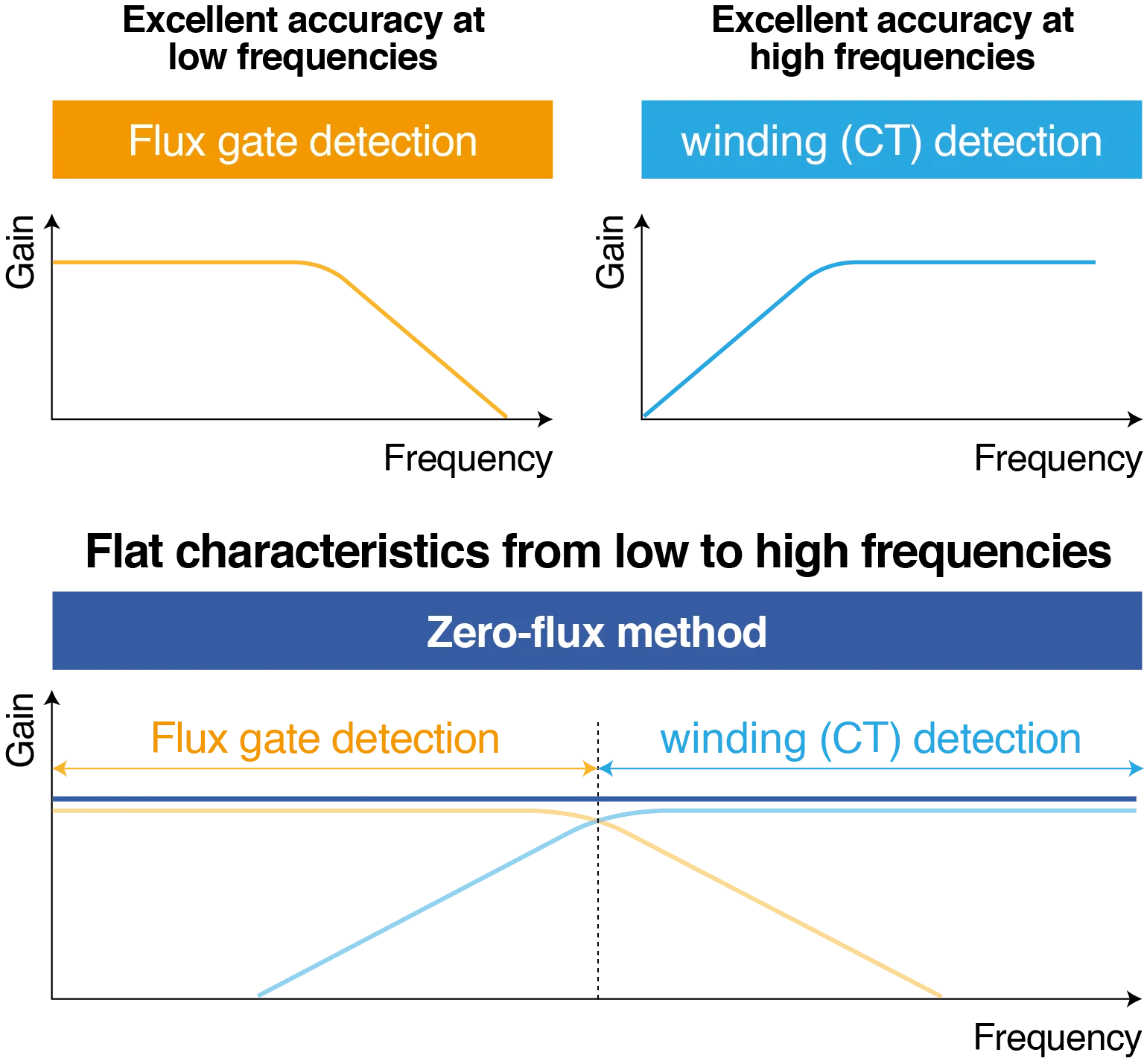

And again you can see the two different current measurement systems: A fluxgate for DC and low frequency AC currents, and a traditional current transducer mechanism for the high frequency AC currents. As with the hall element based current sensors, both signals are added together with flat measurement characteristics from over a wide frequency range.

Fig. 7: Zero-flux sensor with fluxgate: Again, two measurement principles

Conclusion: Zero-flux current sensors with a hall element are best for waveform observations with an oscilloscope as they provide a very high bandwidth. Sensors using a fluxgate don't provide the same level of bandwidth but an extremely high accuracy both with regards to gain and phase. They are also very temperature stable.