HIOKI RM2610 - Measurement System for LIB battery electrode sheets

Electrode Resistance Measurement System, isolates and quantifies the composite layer resistivity and the interface resistance between the composite layer and the aluminum or copper current collector foil of LIB electrode sheets in a single measurement

Product number:

RM2610

Product information HIOKI RM2610 - Measurement System for LIB battery electrode sheets

Key Specifications

- Simultaneously measure composite layer volume resistivity and interface resistance

- Results within a minute

- Contact check function with threshold settings

Unique Advantages

- Calculate composite layer volume resistivity of a battery electrode sheet

- Calculate interface resistance between the composite layer and the collector foil

Typical Applications

- Optimizing the composition of active layer in R&D

- Optimizing production parameters such as temperature and pressure

- Quality assurance in production lines

Detailed Product Overview

The RM2610 calculates two key electrical properties of electrode sheets in a single measurement cycle: the composite layer volume resistivity (Ω·cm) and the interface (contact) resistance (Ω·cm²) between the composite layer and the collector layer, which is either made of aluminum or copper. It employs inverse problem analysis, allowing the system to isolate these parameters accurately – something that was previously difficult due to the complex multilayer structure of electrode sheets.

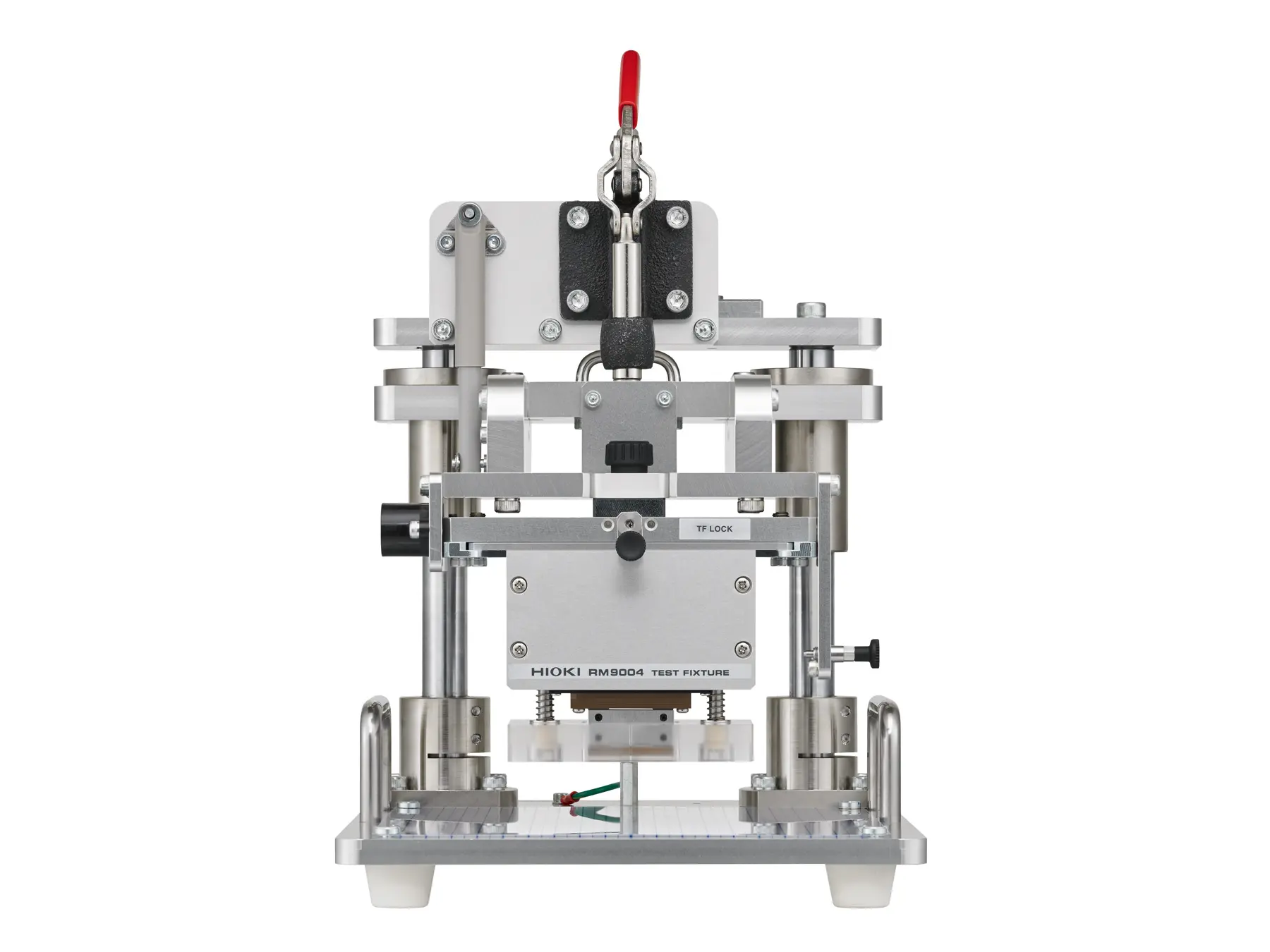

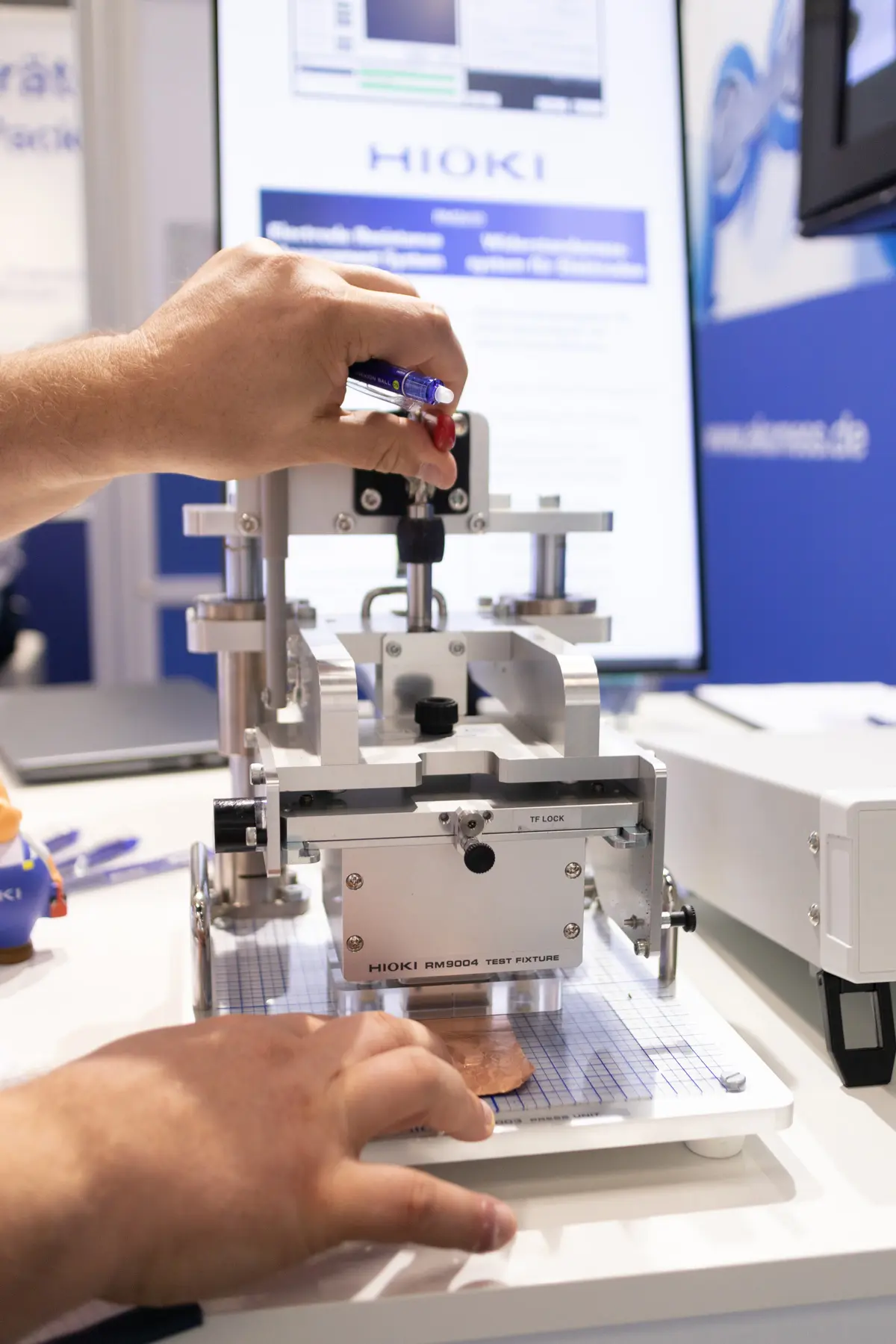

The RM2610 consists of several integrated components. The Electrode Resistance Meter RM2611 performs resistance measurements using the DC 4-terminal method, eliminating the influence of lead and contact resistance. It includes a multiplexer for high-speed scanning and a temperature measurement unit that works with the Z2001 temperature sensor to measure ambient conditions. The Resistance Calculation Software RM2612, running on a PC, controls the entire system and uses advanced numerical analysis to calculate the target resistances. The required PC is not part of the system and must be supplied by the user. The Press Unit RM9003 ensures precise positioning of the Test Fixture RM9004, which houses 46 ultra-fine probes that contact the electrode sheet. These probes are angled to reduce damage during contact. The system is completed by the RM9005 connection cable, which links the measurement unit to the test fixture.

The measurement process starts with the 46 probes contacting the electrode sheet’s surface, after which current is applied between two selected probes to create a three-dimensional potential distribution. This potential is measured and averaged across multiple directions to improve reproducibility. A computational model of the electrode sheet is then created, where the known properties, such as collector thickness and resistivity, are combined with unknown values for the composite layer volume resistivity and interface resistance. The RM2612 software applies the finite volume method (FVM) to solve equations representing potential distributions based on initial estimates for these unknown parameters. The measured and calculated potentials are compared, and the system iteratively adjusts the parameters until both values align. This iterative process ensures that the final output reflects the accurate resistance values.

To guarantee accurate measurements, the RM2610 incorporates several advanced features. An auto-range function selects the optimal measurement range automatically, while a contact check function verifies proper electrical contact for each probe. The system also includes an inspection function that uses a probe check board to test for shorts and opens, ensuring probe integrity. For easy maintenance, the test fixture tilt mechanism allows the probe side of the fixture to tilt forward, facilitating quick cleaning. The software provides indicators such as consistency, error rate, and the coefficient of variability to confirm the reliability of each measurement.

By precisely determining both the volume resistivity of the composite layer and the interface resistance, the RM2610 provides clear, reliable data for evaluating electrode quality. Developers can make faster, well-informed decisions about whether a cell design has potential for further development, while manufacturers gain dependable data to ensure consistently high product quality. This makes the RM2610 a valuable tool for optimizing materials and production processes – an essential factor in meeting the growing demands of electric vehicles, consumer electronics, and renewable energy applications.

- RM2611 Electrode Resistance Meter

- RM2612 Resistance Calculation Software

- RM9003 Probe Press Unit

- RM9004 Probe Head

- RM9005 Connection Cable

-

Product brochure with data sheet, ELECTRODE RESISTANCE MEASUREMENT SYSTEM RM2610 (English)2,480 KB pdf

-

Instruction Manual, ELECTRODE RESISTANCE MEASUREMENT SYSTEM RM2610 (English)5,934 KB pdf

-

Instruction Manual, ELECTRODE RESISTANCE METER RM2611 (English)1,022 KB pdf

-

Instruction Manual, ELECTRODE RESISTANCE METER RM2611 (German)1,686 KB pdf

-

Instruction Manual, TEST FIXTURE RM9004 (English)2,295 KB pdf

-

Product Catalog, Measuring Instruments for the Battery Industry (English)6,753 KB pdf